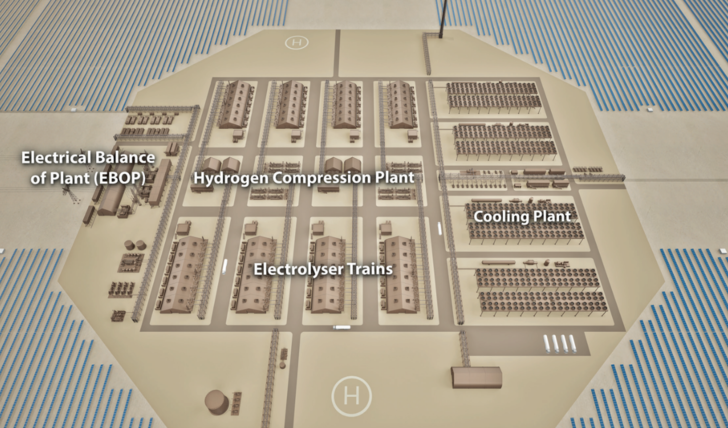

After four years of development, the company is now presenting a solution that, similar to standardized shipping containers, is designed to standardize hydrogen production. Instead of custom-designed projects, Intercontinental Energy is pursuing a standardized, modular approach.

A key feature of the system is the direct co-location of hydrogen production with wind and solar farms. In contrast to conventional centralized models that require costly electricity transmission, the electricity is used directly at the point of generation. This avoids transmission losses and increases overall efficiency.

„The P2(H2)Node architecture is a breakthrough in clean hydrogen production. By eliminating transmission losses and applying a modular approach, we are making green hydrogen cost-competitive at scale for the planet," explains Alexander Tancock, CEO of Intercontinental Energy.

The company promises up to 10 percent lower capital expenditure, up to 10 percent higher efficiency, and more consistent customer supply thanks to integrated storage.

Mega-hub in Australia to deliver 70 GW of renewable energyThe P2(H2)Node architecture forms the backbone of the Western Green Energy Hub (WGEH) in Australia. With a planned capacity of 70 GW of renewable energy, WGEH is set to become the world's largest and most cost-efficient green hydrogen hub. Supported by new government incentives in Australia, the production cost of green ammonia is expected to fall below USD 650 per tonne.

According to Intercontinental Energy, the company is working with global partners to deploy the P2(H2)Node architecture and accelerate industrial decarbonization. The system is intended for use in sectors such as green steel production, fertilizer manufacturing, power generation, and marine and aviation fuels.