The demand for hydrogen in road freight transport in Germany is estimated to increase to up to 2 million metric tons per year by 2045. In this scenario, nationwide supply will require the construction of more than 2,000 H2 filling stations. The planned core H₂ network, which is to reach a total length of 9,700 kilometers (6,025 miles) by 2037, can play a central role in this. It consists of 60 percent repurposed natural gas pipelines and is to be gradually supplemented by distribution networks in order to open up regions away from the main routes. The network will not only be able to serve industry and power plants, but also other sectors such as the mobility sector, creating a flexible and resilient hydrogen infrastructure.

The role of H₂ hubs

One of the key findings of the study is that it is economically attractive and technically feasible to supply HRSs via the H₂ pipeline network. The technical-economic analysis of the four supply options shows that an H₂ hub, which acts as a central supply point for a number of other HRSs and is connected to the H₂ core network, is the most attractive option.

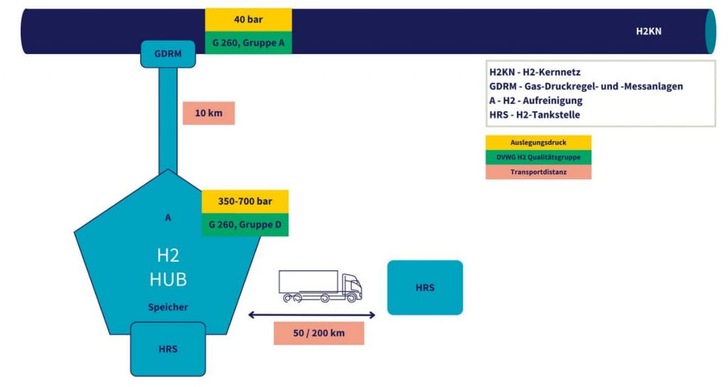

Fig. 2: HRS supply by trailer from an H₂ hub connected to the core H₂ network. This is the preferred connection option to the H₂ pipeline network in the study.

The H₂ hubs act as links between the core H₂ network and the regional filling stations and are directly connected via a spur line. They take over central processes such as the purification, compression and storage of hydrogen. This achieves economies of scale that not only reduce costs, but also reduce the technical requirements for operating the filling stations. The hydrogen is then distributed by trailer at different pressure levels to the surrounding filling stations – the study assumes a radius of 50 kilometers (31 miles). Depending on capacity utilization, it is also conceivable to supply customers who do not come from the mobility sector but have similar hydrogen quality requirements.

H₂ hubs also offer flexibility in the integration of different hydrogen sources. They can be supplied via pipelines from the core network (the subject of the study), by local electrolysis or by other means of transportation such as trains and ships (this was not investigated in the study). This makes them a key building block for efficient and sustainable hydrogen mobility in Germany.

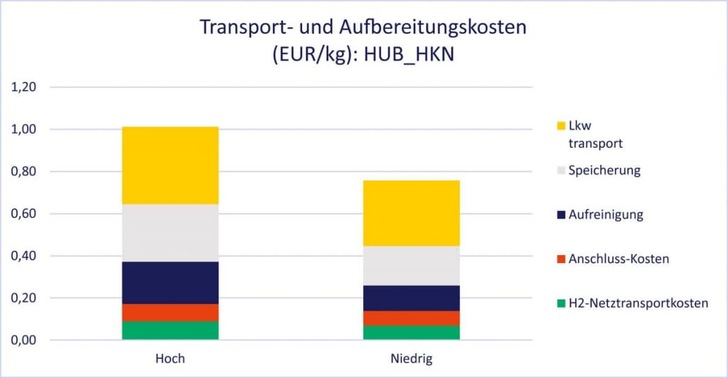

Fig. 3: Specific transportation and processing costs for H₂ supply by trailer from an H₂ hub with connection to the core H₂ network: cost components in two different scenarios of the preferred connection option for 2030.

Technical and regulatory challenges

Ensuring the quality of hydrogen for use in fuel cell vehicles is one of the key challenges facing H₂ hubs. The hydrogen obtained from the pipeline must be processed in accordance with the purity requirements of DIN EN 17124, which requires additional investment in innovative technologies. It is equally important that grid charges and grid connection fees are set promptly in order to create planning security for investors.

Transportation distances are a major cost driver. The positioning of H₂ hubs near regions with a high demand for hydrogen and a high density of filling stations is therefore crucial. At the same time, a regulatory framework must be created that enables the smooth integration of H₂ hubs into the existing infrastructure.

Recommendations for the structure

The study formulates nine specific recommendations for action to create an efficient supply of hydrogen filling stations via an H₂ pipeline network:

- Integration of planning: H₂ networks and filling station infrastructure must be closely interlinked during development in order to exploit synergies.

- Demand assessment: The establishment of a central platform for recording hydrogen demand facilitates the planning and identification of suitable H₂ hub locations.

- Location criteria: The development of transparent criteria for the location selection of H₂ hubs promotes targeted planning.

- Identification of possible H₂ hub operator models, in which local players should also be actively involved in order to strengthen regional value chains.

- Piloting: An initial H₂ hub should be piloted by 2030 in order to gather practical experience and identify optimization potential.

- Further investigation of the key aspect “hydrogen quality”: How and at what cost can the purification of the hydrogen extracted from the pipeline be guaranteed (with fluctuating quality/different impurities)?

- Technology development: Further developments in hydrogen processing and compression are essential in order to achieve economies of scale.

- Grid charges: Early determination of grid charges and connection fees creates investment security.

- Holistic analyses: The investigation of the effects of pipeline supply via the H2 network should also be extended to other areas (ecological, social, etc.).

Conclusion

The results of the study show that hydrogen filling stations can be supplied with hydrogen efficiently, sustainably and economically via an H₂ pipeline network in the future. H₂ hubs have a central role to play here. If the proposed recommendations for action are implemented, they could become a key component of a sustainable hydrogen infrastructure.

The long-term goal is to ensure a nationwide hydrogen supply that integrates not only the transport sector, but all applications. This requires close cooperation between politics, industry and science in order to ensure the technical feasibility and economic viability of such a sustainable hydrogen infrastructure. H₂ hubs offer a flexible and scalable solution that allows the infrastructure to be gradually adapted to increasing demand.

Literature:

NOW GmbH & dena: “Versorgung der H₂-Tankstelleninfrastruktur in Deutschland über ein H₂-Pipeline-Netz ,” 2024.

Author: Carsten Beyer, NOW GmbH, Berlin, Germany