U.S.-based hydrogen technology provider Utility Global and steel group ArcelorMittal have launched a joint project for decentralized hydrogen production at ArcelorMittal’s Juiz de Fora site in the Brazilian state of Minas Gerais. The aim is to use Utility Global’s H2Gen system to extract hydrogen from blast furnace gas.

The project is currently in the so-called Front-End Engineering and Design (FEED) phase. In this phase, the technical and economic feasibility of using the H2Gen system on site is being evaluated. Utility Global is responsible for the engineering management.

High-purity CO2 facilitates capture and storage

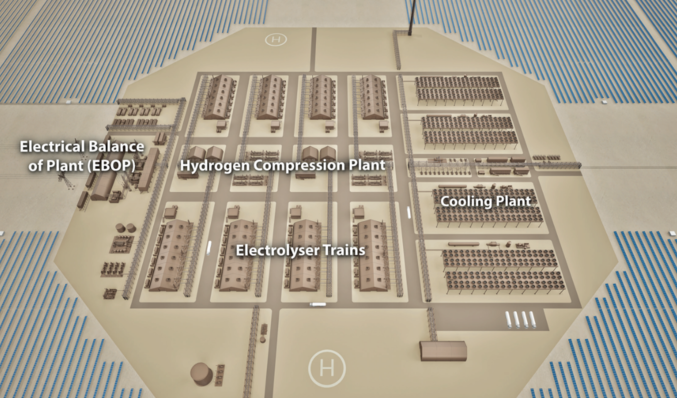

The H2Gen system is based on a patented reactor that converts industrial process gases – in this case, blast furnace gas – into high-purity hydrogen and concentrated CO2 without the use of electricity. The hydrogen produced can be used in the steelmaking process as a substitute for natural gas. The resulting CO2 is in high-purity form, which facilitates capture and storage and reduces costs.

According to Utility Global, the system is expected to be capable of producing up to three tons of hydrogen per day. The technology is designed to be modular and scalable, enabling on-site production with low CO2 intensity. “This project represents our shared commitment to advancing business and technology innovations that support global energy transition goals,” says Parker Meeks, CEO of Utility Global.

ArcelorMittal is also an investor

ArcelorMittal is not only a project partner but also an investor. Through its XCarb Innovation Fund, the group has invested five million U.S. dollars in Utility Global. The fund was established in 2021 to support technologies for decarbonizing the steel industry.

“Our goal has always been not only to support our portfolio companies financially, but also to provide them with access to our global sites as testbeds for new technologies. We see great potential in Utility Global’s H2Gen system,” explains Irina Gorbounova, Head of the XCarb Innovation Fund.