The Emscher-Lippe region, located in the heart of the northern Ruhr area in Nordrhein-Westfalen, extends south of Münsterland and is part of the administrative district of Münster. This results in close links between the region and neighboring areas, both politically and technologically. The region is also characterized by the combination of conurbations in the southern part of the region and the more rural parts in the north, forming interfaces between traditional industry and modern innovation in many places. With the independent cities of Bottrop and Gelsenkirchen and the ten towns in the district of Recklinghausen, the Emscher-Lippe region is the center of life for around one million people.

Our region is known for its industrial tradition, which has been undergoing structural change for many years now. It has over 30,000 companies, two universities and 15 vocational colleges, which have already adapted their courses specifically to the technological developments in the hydrogen sector. In addition to a well-developed road and highway network, the region also has a dense rail and canal network as well as numerous pipelines. We are also creating synergies for our future strategy with the neighboring Münsterland region and the adjacent Hellweg zone. We also work closely with the Netherlands, for example with the joint project TECH.LAND

H2ere you can experience the future

A unique selling point of our region is its particular suitability and experience for the hydrogen economy. Due to the well-developed pipeline infrastructure and major buyers of hydrogen, its ramp-up can take place faster and more cheaply here than in other parts of Europe. In addition to regional customers, several chemical sites (e.g. in Cologne or Leverkusen) purchase hydrogen from our region.

However, we not only cover production and use, but also comprehensively map the other important areas of the value chain. These include a large number of companies that specialize in the development and manufacture of components, as well as other companies that act as providers of technologies and innovative solutions.

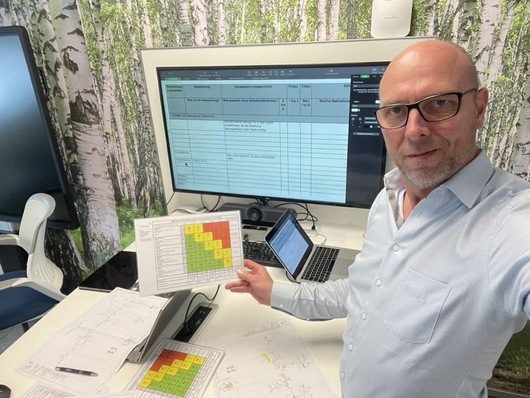

Fig. 2: Hydrogen roadmap

In our new roadmap, we provide an up-to-date overview of relevant hydrogen-related projects that are being implemented in our region or are in the planning or idea phase. In addition to the H2 roadmap, we are continuously monitoring the projects in order to create transparency and guidance for the market ramp-up in the region.

Widely positioned

The project portfolio represents the core of our roadmap and provides information on how the H2 requirement from 2024 to 2032 will probably develop. The projects are divided into the following five fields of action: city quarters, qualifications, research & development, industry and mobility. When we look at the total number of the projects, it turns out that we have taken significant steps in recent years. Originally 57 projects in 2021 have become over 100 in almost three years. A strong growth is recorded in particular in the implementation of the projects. While there were still 17 in 2021, it is now 53. The increase is particularly striking in the field of action industry.

Leuchtturm projects

Our project portfolio contains all hydrogen-related projects in the region, and some of them should be emphasized. Among other things, the electrolyzer planned by Air Liquide in the Marl Chemical Park with an output of 120 MW. This will generate green hydrogen, which is to be transported to customers using remote lines or via the hydrogen core network. This is an IPCEI project that received the funding notice in July 2024.

The following two pioneering Leuchtturm projects can be found in Gelsenkirchen:

On the one hand, an entire industrial area has set off with the city harbor to become climate-neutral. For this purpose, the local companies have come together for the initiative "Klimahafen Gelsenkirchen". Process heat (around 500,000 MWh) is to no longer be generated here by natural gas, but by green hydrogen. Until the green hydrogen is available, companies will use a hydrogen-rich gas energy source.

On the other hand, the university Westfälische Hochschule is strengthening its research focus in the field of hydrogen technologies. Among other things, with “H2 Solution Lab” will appear a new laboratory building for the development of knowledge with regard to components, subsystems or total systems for research and transfer.

In Haltern am See, several energy-intensive companies plan to drastically reduce their CO2 emissions by using green hydrogen. A combined annual hydrogen requirement of around 200,000 MWh is expected, which is to be covered by an electrolyzer, fed by local wind and solar power. Haltern am See could also in the future be connected to the nearby hydrogen core network.

In Herten, the Anwenderzentrum H2herten has existed since 2009, a communal technology center for hydrogen, which self-sufficiently supplies itself through renewable energies. The existing premises and the technical center, including the first complementary energy system (wind power with electrolysis) in Germany, companies can use for investigations of various types. With the system, components can be tested under real conditions or special load cases can be simulated. The complementary system takes on the intelligent control of components, current flow and hydrogen production. In and around the technology center have settled since its completion topic-related companies and institutions, such as the engine manufacturer Cummins Inc. or TÜV Nord.

In the immediate vicinity of the user center is a system from AGR mbH. This creates electricity and district heating to supply the adjacent residential areas by burning waste. In 2024, a 3-MW PEM electrolyzer was installed, which produces hydrogen, and a connected H2 gas station was provided. Electricity can be obtained from the burning of waste and from own regenerative energy sources (solar and wind). The gas station, via the pressure levels 700 bar and 350 bar, is suitable for refueling cars, trucks and AGR’s trash collection vehicles and is currently the largest H2 refueling station across Europe.

The project E-BO(2)t is a demonstration project by the water board Emschergenossenschaft and some project partners in the nearby city of Bottrop. The goal is to test the feasibility of a large-scale production of green methanol (e-methanol) on a sewage treatment plant. For this purpose, biogenic CO2, which is created in the rotting towers of the Bottrop sewage treatment plant, is split off from the sewage gas and brought together with green hydrogen produced on site in order to synthesize the electric methanol and to be able to use it as an alternative fuel. As a by-product of hydrogen production, pure oxygen is created, which is directed to nearby water resources for ecological improvement.

In addition to these Leuchtturm projects, numerous other initiatives and projects are being planned. Many of these projects focus on significantly reducing the use of fossil energy sources, especially natural gas. An important approach here is the substitution of natural gas by green hydrogen as an energy source for the generation of process heat, which is essential in many industrial processes. The aim of this changeover is of course the reduction of greenhouse gases and the associated reduction in natural gas demand.

Outlook

On the basis of our project portfolio and the quantity forecasts for 2032, an annual need of around 6.5 TWh hydrogen is expected in the region, which corresponds to around 200,000 tonnes per year. Although we are expected to exceed our self-placed expansion objectives for electrolysis capacity for 2032, we cannot cover our growing need for hydrogen through own production and therefore have to import hydrogen on a large scale in the future. If all known electrolysis projects are realized, the amount of domestic production will be around 40 percent. By substitution of natural gas through this green hydrogen, we can save over 1.3 million tonnes of CO2 equivalents.

Author: Marc Luckhaus, WiN Emscher-Lippe Gesellschaft zur Strukturverbesserung mbH, Herten