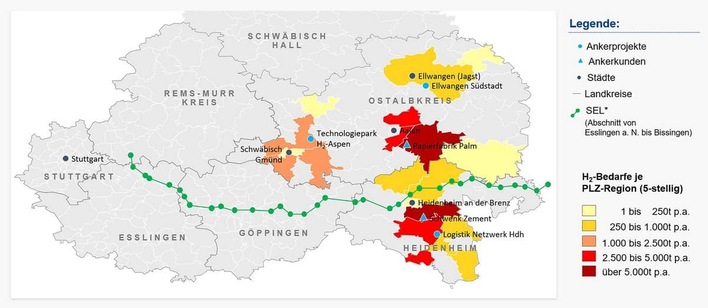

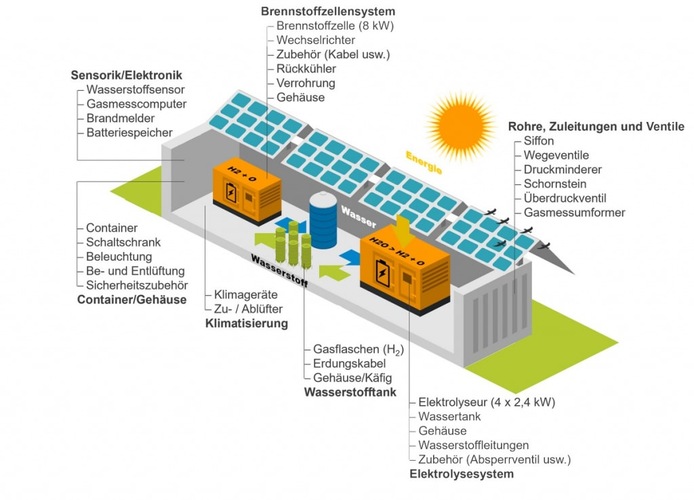

Fig. 1: Hydrogen Tryout Area

Hydrogen-based microgrids can be flexibly adapted to different application scenarios. They are therefore primarily used for decentralized supply in rural areas, but also in urban conurbations and to support industrial production and processes as a real alternative to CO2-producing diesel generators. If the industrial production of microgrids can be successfully established, this will benefit manufacturers (industrial value creation), local communities (stable energy supply) and climate protection (CO2-neutral energy production) in equal measure.

HyTrA – Hydrogen Tryout Area in Cape Town, South Africa

The Hydrogen Tryout Area, funded by Germany’s Federal Ministry for the Environment, Nature Conservation, Nuclear Safety and Consumer Protection (BMUV), is ideally suited to demonstrating the effectiveness of hydrogen for a stable, climate-neutral energy supply. Especially for regions that have surplus renewable energy and are potential exporters of hydrogen, HyTrA offers them the opportunity to use hydrogen themselves.

General conditions

South Africa’s economy and energy production are heavily dependent on coal. The country is also one of the 20 largest greenhouse gas emitters in the world. Its electricity supply is very patchy: South Africa’s state-owned energy company Eskom has had to ration electricity supplies for its 60 million customers for more than a decade. The outdated infrastructure results in an estimated annual power deficit of 4 gigawatts, which corresponds to the demand of around 10 million households. A stable energy supply is the basis for socially oriented economic growth and indispensable in the fight against poverty and inequality – solutions for a secure supply of renewable energy are urgently needed in South Africa.

HyTrA is installed close to industry at the company Alu-Cab, a manufacturer of car roof tents and accessories in Cape Town. Alu-Cab already has photovoltaic systems on site and can now also use the surplus energy to produce hydrogen on the premises, store it and convert it back into electricity when required. Thus the microgrid ensures that the company has a stable power supply for its production.

Solution overview

The central component of HyTrA is a robust and cost-effective microgrid specially designed for the African market by Texulting GmbH and Fraunhofer IWU. This innovative solution forms the centerpiece of a Hydrogen Tryout Area, which also has a technology showcase designed to arouse companies’ interest in component manufacturing, assembly and installation. HyTrA is also integrated into a socio-economic and socio-ecological H2 framework, which emphasizes environmental aspects through accompanying information and training offers, which fundamentally contribute to the acceptance of hydrogen and count towards the Social Development Goals (SDG) of the United Nations.

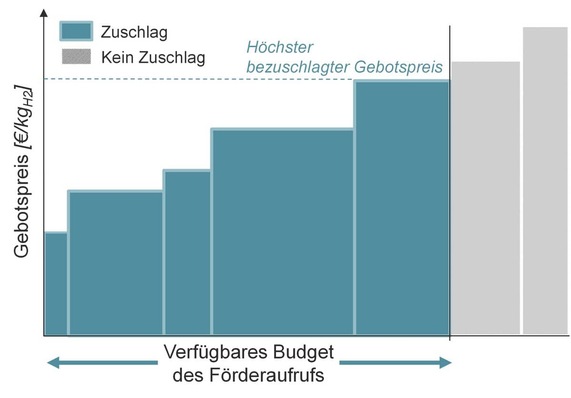

Microgrid

To this day, fossil fuel-powered generators play a central role in South Africa as emergency power generators or to support the unstable and, in some locations, inaccessible energy supply. The aim in developing and testing the compact 8-kW hydrogen microgrid was to offer an efficient and robust alternative at comparable cost. Complete power-to-power sector coupling is integrated into the compact H2 microgrid unit. All the microgrid components required are contained in a transportable housing. The electricity generated by solar cells is used to split water into hydrogen and oxygen in the electrolyzer. The hydrogen is compressed and stored in suitable gas cylinders. If electricity is required, the hydrogen can be converted back into electricity via a fuel cell stack through the introduction of ambient air (oxygen). The waste product is water, which is stored in a tank and made available for electrolysis as required. This creates a closed water cycle for which water only has to be provided at the beginning and which subsequently operates almost loss-free.

The microgrid thus integrates and links various components that ensure hydrogen production, storage and reconversion resulting in a decentralized power supply independent of the changing availability of renewable energies and enabling seasonal storage of green energy. The key here is a modular, closed structure that allows for a largely maintenance-free, flexibly scalable and easily adaptable system.

Fig.2 : Microgrid structure

The microgrid developed as part of HyTrA is a self-sufficient energy network in a small and compact format. What makes it unique is that it is perfectly adapted to the specific requirements of the African market. With a service life of over 60,000 operating hours (more than 10 years), it represents a robust and safe technological solution. The system offers new possibilities in terms of storage density, safety, user-friendliness, maintenance-free operation and energy self-sufficiency. Based exclusively on renewable energies, the system is the key to a decentralized power supply that also covers off-grid and hard-to-access areas.

Technology showcase

The hydrogen technology showcase makes the microgrid transparent as a virtual reference grid. The digital image shows how the physical system works, what advantages it offers, which system components it comprises and how they are integrated. It also serves to market HyTrA across regions. It allows access to functional data from Germany and thus ensures a continuous exchange of information and increased cooperation.

Specific tests and field trials with the microgrid components deployed provide results that serve as a basis for further development. The aim is to successively improve the robustness of the system and optimize its use in climatically and socio-economically challenging areas. Component manufacturers in Germany can use data to adapt their products for use in the African market and refine standards. This makes risk-minimized expansion possible.

Extended framework

The broad framework also expands HyTrA’s scope. For example, joint ventures have been initiated between German and African companies. The establishment of regional supply chains has also been promoted. Needs-oriented support services and information offerings make it easier for German companies to tap into the African market, and local companies interested in a secure energy supply and the integration of hydrogen into their processes can make use of the services of German companies.

Marketing, consulting, sales and customer support are aimed at establishing the microgrid as a climate-neutral alternative to fossil-fueled generators. The exchange of scientific ideas relating to hydrogen is also being encouraged. The development of the microgrid therefore provides starting points for research cooperation, particularly on technological and economic aspects.

Last but not least, the transfer of knowledge is of central importance so that local communities can use the new technologies sustainably and independently. For example, cooperation with the d-school of the Hasso Plattner Institute in Cape Town has been continuously extended. In particular, a design thinking challenge has aimed to improve access to clean energy for rural farming communities. Over a period of 10 weeks, students developed innovative prototypes and solutions for the specific challenges faced by these communities.

Commissioning and accompanying measures

On July 13, 2023, HyTrA was ceremoniously put into operation in Cape Town in the presence of the Mayoral Committee Members for Energy in the City of Cape Town, representatives of NOW and Z.U.G. and supported by a greeting from the BMUV. The project team from Fraunhofer IWU, Texulting GmbH, Alu-Cab, Stellenbosch University and Umstro GmbH produced the first hydrogen on African soil, which was then converted back into electricity for a specific industrial application at Alu-Cab.

HyTrA is an important cornerstone for building a bridge between Africa and Europe with hydrogen. Unlike the megawatt and gigawatt projects of large investors, this project is designed for the use of hydrogen in Africa. An equal partnership approach will create long-term benefits for both sides.

The initiative will make use of systems and expertise from Germany. The participating SMEs and scientific partners in particular can gain important experience as well as gather usage data for further developments by using the system in practice. The microgrid also provides a basis for the applied training of urgently needed specialists. It is currently undergoing a long-term test, which is providing valuable data on service life and performance. This data will help to improve the next generation of components.

With appropriate scaling on both sides, hydrogen will become an export commodity for Africa and play a major role in supporting Germany’s energy transition.

HygO – water treatment in Namibia

HygO is another pioneering H2 project in the starting blocks. In addition to the functionalities of the HyTrA system, the project, which is likewise funded by the BMUV, will also use the oxygen produced during electrolysis. The plan is to use this for the treatment of wastewater. Other industrial partners have been involved in the project. Haver & Boecker OHG and Krenkel Abwassertechnik GmbH join Texulting GmbH and Fraunhofer IWU as new members of the project team. The microgrid is currently being set up at Fraunhofer IWU. The intention is to put it into operation in a remote area in the Erongo region of Namibia from June.

Fig. 3: Governor Neville Andre (Erongo District, Namibia) – with Dr. Ulrike Beyer on his right

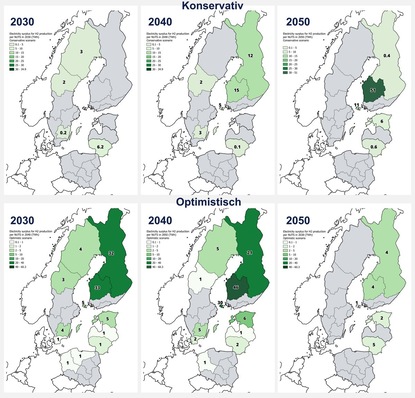

HyGrid for the reconstruction of Ukraine

With HyGrid, the Fraunhofer-Gesellschaft is promoting a cost-effective and robust microgrid based on the hydrogen system solutions HyVentus (electrolyzer) and HyVictus (fuel cell) developed at the Fraunhofer IWU Chemnitz. The aim is to create a particularly economical demonstrator microgrid as a blueprint for the industrial series production of such systems. These hydrogen-based microgrids will be used in the reconstruction of Ukraine and will stabilize the power supply, which has been severely damaged by the war. Thanks to the scaled plug-and-play design, they can cover the range from a few to several hundred kW – ideal for the needs of hospitals, businesses, schools or remote rural areas. The core task of these microgrids is also to store renewable energy over a longer period of time and to convert immediate energy surpluses into hydrogen so that the latter can be converted back into electricity during periods when there is little sun or wind. HyGrids will contribute to the energy supply next winter.

Fig. 4: Scheme for the reconstruction of Ukraine through economic solutions for decentralized energy supply

Hydrogen-based microgrids also appealing to Germany

The visibility of the African activities of Fraunhofer IWU and its participating industrial partners has also led to numerous inquiries about the use of hydrogen-based microgrids in Germany. In particular, the option to use the oxygen produced during electrolysis for water treatment represents a unique selling point. For example, many requests for decarbonization come from sports centers that want to reconvert the hydrogen produced during the day into electricity for the operation of floodlights. The oxygen obtained could be used to purify or disinfect water and utilized in swimming pools or to irrigate field hockey pitches. The waste heat from the microgrids could also be used to heat utility buildings, for example.

Hydrogen-based microgrids are suitable for numerous decentralized energy supply applications and also offer other advantages that further increase their effectiveness. They represent considerable value creation potential for the German economy, both directly in the production of the required system components and in terms of cooperation with Africa in the future.

Author: Dr. Ulrike Beyer, Referenzfabrik.H2 at the Fraunhofer Institute for Machine Tools and Forming Technology IWU, Chemnitz