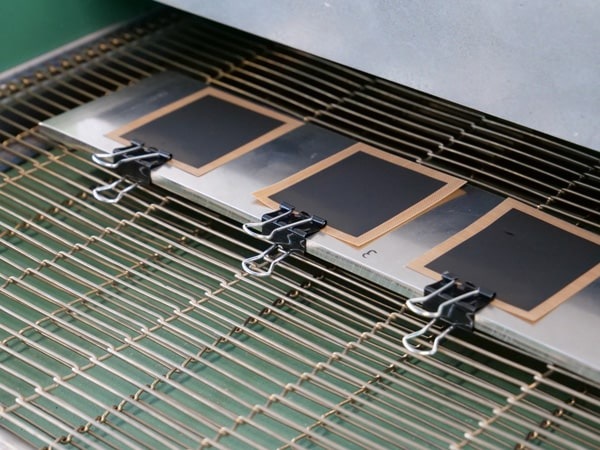

The German transportation ministry is funding Fraunhofer ISE as coordinator of R2MEA, a subgroup of the H2GO project, and the Fraunhofer institutes ENAS, ICT, ILT, IPT and ISI in order to support component manufacturers as well as plant and machinery construction companies in their development through in-depth research. A research platform is being developed and created within R2MEA that will be available to companies in the future for investigating production issues ranging from catalyst manufacturing to finished 7-layer MEAs (comprising a membrane, catalyst layers, support frame and gas diffusion layers).

R2MEA tackles research issues for MEA production

Today’s system designs need to be adapted to enable the mass manufacturing of membrane electrode assemblies in sufficient volumes. The associated issues are tackled as part of the R2MEA initiative:

- How can current production of catalyst powder be switched from batch processes to continuous processes?

- In addition to the dominant slot die coating technique, are rotational printing processes advisable for the application of catalyst layers, for example, to replicate specific formats and save cutting waste? Is it possible to print directly onto the membrane while ensuring the necessary quality? Can laser drying processes shorten the drying time and the dryer length?

- How can membrane, catalyst layers, support frames and gas diffusion layers be cut to size in roll-to-roll processes? How is distortion-free sheet conveying made possible for these different sheet goods? Which positioning and laminating processes are suitable for producing high-quality composites of single layers?

- How should transport containers for semifinished products be devised for internal and external logistics to enable seamless processes?

Extensive market studies on industry requirements, technical and economic analyses on the viability of different production processes and life cycle analyses on the ecological footprint are being conducted to accompany the setup of the research platform.

The R2MEA subgroup is currently coordinating the various processes that are to be investigated in the course of the project. In addition, the necessary equipment is being acquired and laboratories built. In parallel to this, scientific investigations are being carried out and the knowledge gained on a pilot level is being passed on.

Fuel cell production research at hy-fcell

The topic of production research for fuel cells is among those being addressed at the hy-fcell conference and trade fair on Sept. 13 and 14, 2023, in Stuttgart, Germany, in a dedicated two-day session under the coordination of the Fraunhofer institutes participating in H2GO. The event will provide the stage for international speakers from science and industry who will discuss all aspects involved along the process chain. Three individual sessions on value creation from catalyst manufacturing to the MEA will be led by Fraunhofer ISE, Freiburg, and the Center for Solar Energy and Hydrogen Research (ZSW), Ulm.

Fraunhofer production research for H2GO

The overarching H2GO group involves the participation of 19 Fraunhofer institutes from nine German states. The institutes are tasked with developing solutions for the industrial series production of fuel cells with a focus on heavy-duty road transportation. H2GO is funded by the German transportation ministry to the amount of EUR 80 million. Responsible for overall coordination is Fraunhofer IWU under Ulrike Beyer.

Fraunhofer ISE leads the R2MEA subgroup in which roll-to-roll processes are being developed for scaling up MEA production from catalyst powder to 5-layer membrane electrode assemblies, i.e., the combination of membrane, catalyst layers, support frame and gas diffusion layers.

Other subgroups are working on the manufacture of bipolar plates: R2HP (roll to half plate with the associated forming and cutting processes), HP2BPP (half plate to bipolar plate with the corresponding joining, coating and cutting processes). The ST2P (stack to piece) subgroup concentrates on the disassembly of fuel cell stacks in order for individual components to be fed into a circular economy. The overseeing NEXUS group ViR (virtual reference factory) is developing digital images of the devised production solutions, enabling it to create virtual reference architecture for fuel cell production.

Authors: Ulf Groos, ulf.groos@ise.fraunhofer.de, Linda Ney, Both from Fraunhofer Institute for Solar Energy Systems ISE, Freiburg, Germany