The Indian chemical manufacturer TGV SRAAC Ltd. has commissioned Thyssenkrupp nucera to expand its chlor-alkali plant in Kurnool, Andhra Pradesh. The core of the project is the implementation of the latest generation of BiTAC® technology, which enables energy-efficient and safe caustic soda production. With the expansion, the plant’s production capacity will increase from the current 1,000 tons to 1,500 tons per day. This corresponds to an annual production volume of approximately 500,000 tons of caustic soda.

“This is a milestone project for us, especially as it involves a significant expansion of our plant. We are convinced of Thyssenkrupp nucera’s technology and are very much looking forward to receiving a state-of-the-art facility from them,” said T.G. Venkatesh, Chairman of the TGV Group.

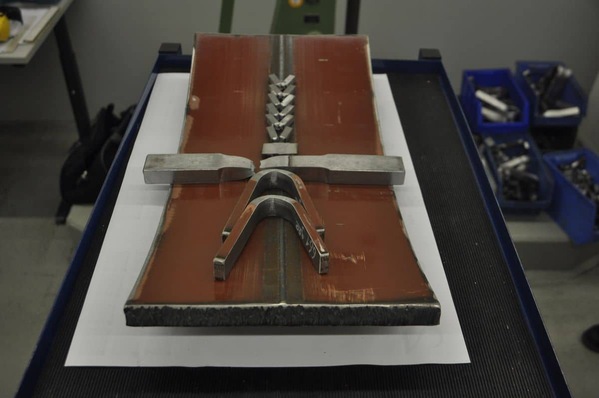

The eBiTAC v7 technology supplied by the German plant engineering company is based on the proven bipolar ion-exchange membrane electrolyzer BiTAC®. This technology is characterized by particularly low energy consumption and supports resource-efficient production. In addition to the proprietary cell elements, the engineering package includes the entire cell room with electrolyzers and associated equipment.

Dr. Roland Beckmann, Executive Director Chlor-Alkali at Thyssenkrupp nucera, emphasized: “This project is a testament to our capabilities and our commitment to innovation. It also symbolizes the synergies within our group, as our China office is working together with our India office to support the customer in this project.”

The collaboration between TGV SRAAC and Thyssenkrupp nucera goes back more than two decades. As early as 2004, the Indian company relied for the first time on the German manufacturer’s bipolar membrane technology to expand the production capacity of its chlor-alkali plant. Since then, the Dortmund-based electrolyzer supplier has repeatedly supported capacity expansions.

With the capacity expansion in Kurnool, TGV SRAAC is strengthening its position as a leading manufacturer of caustic soda in India. The implementation of the energy-efficient BiTAC® technology is not only another step in the long-standing partnership with the German company, but also a contribution to sustainable chemical production in India.

The successful implementation of this project could serve as a model for further plant modernizations, particularly in regions that depend on resource-efficient technologies.