Six million trucks are on the road across Europe every day, covering 300 billion kilometers annually and consuming 60 million tonnes of diesel. They require 700 TWh of energy per year and emit around 200 megatonnes of CO2 annually. At least, these are the figures provided by Daimler Truck in 2024.

Since hydrogen engines and fuel cell drives still offer advantages over battery-electric propulsion for long distances and heavy loads, truck manufacturers are relying on this technology to decarbonize their vehicles.

Cellcentric aims to set standards

In 2021, Daimler Truck joined forces with the Volvo Group to cooperate on fuel cell technology, share costs and, above all, establish a certified standard that the entire industry will ultimately have to adopt. In March 2021, Volvo acquired a 50 percent stake in Daimler Truck Fuel Cell for €0.6 billion. Together, they founded the company Cellcentric, whose business purpose is to develop, produce and market a fuel cell system for long-haul trucks. Since then, 700 experts have been working for the joint venture in the the southern German cities and towns Nabern, Stuttgart-Untertürkheim, Esslingen, and as well in Burnaby, Canada. The experts have generated 700 patents.

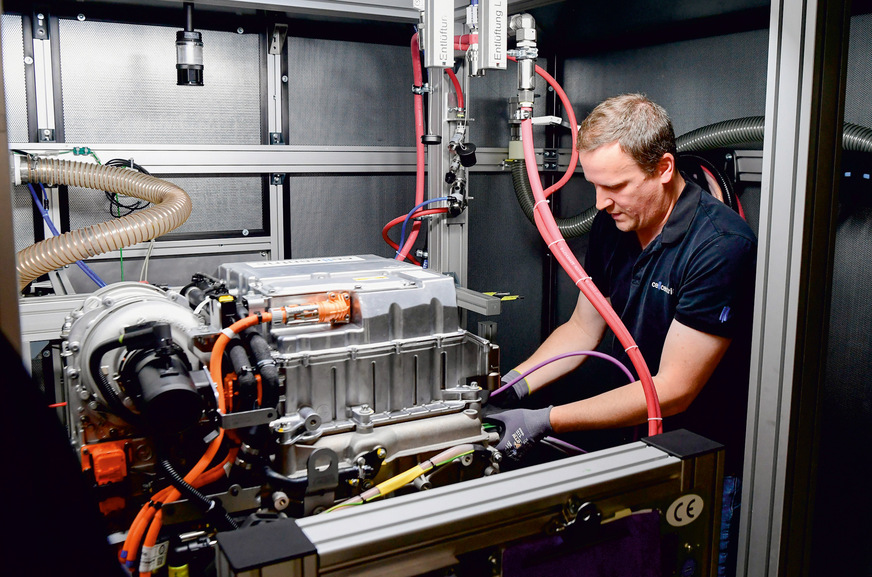

In June 2024, Cellcentric launched pilot production of fuel cells in Esslingen – directly on the B10 highway, with 10,300 square meters of production and storage space including offices and 100 employees. The first fuel cells are being installed in truck prototypes. At the same time, a high level of automation is to be developed, ensuring high quality and future recyclability, with the aim of enabling large-scale production in nearby Weilheim starting in 2026.

Reference project for supply chain development

Since this year, the German Federal Ministry for Digital and Transport, along with the Federal States of Baden-Württemberg and Rhineland-Palatinate, has been supporting Daimler Truck with €226 million to build a fleet of 100 hydrogen trucks. This fleet is scheduled to enter continuous operation from the end of 2026 with five reference customers, including Amazon. The funding covers two-thirds of the costs. This is permissible under EU law, as it qualifies as an Important Project of Common European Interest (IPCEI). These trucks are being built at the Daimler plant in Wörth. Their deployment will provide operational and maintenance experience.

The reference project is also intended to enable the development of a supply chain: the electric drive axles come from the Daimler plant in Kassel, the “Teck Tower” from Mannheim, and the fuel cells from Cellcentric in Esslingen. Part of the assembly is also carried out at the Daimler plant in Gaggenau.

Subcooled hydrogen to reduce costs

The basis for the project is the further developed GenH2 Truck tractor unit, which is already being produced in Wörth. A key factor in the funding decision was the variant using subcooled liquid hydrogen (sLH2), which is said to be significantly more cost-effective and powerful than gaseous compressed hydrogen. Cooling to around -260 degrees Celsius is intended to prevent boil-off and enable pressure-free refueling, while also reducing volume.

This should allow the vehicles to match conventional combustion engines in terms of performance and range, as Daimler Truck demonstrated in September 2023 under real-world conditions on public roads with a range of 1,047 kilometers. So far, one liquid hydrogen (sLH2) refueling station is available in Wörth and one in Duisburg, which should be sufficient for the five reference customers.

Expanding refueling infrastructure requires cooperation

Infrastructure is just as important for battery-electric vehicles as it is for hydrogen trucks. Fortunately, energy providers are investing in charging infrastructure in line with the growth of the zero-emission vehicle (ZEV) fleet, according to Daimler. In addition, operators are making advance investments to secure future markets.

Hydrogen infrastructure is more complex. For sLH2 refueling stations, Daimler has been working with Linde Engineering since last year. Their technology enables 80 kilograms of hydrogen – enough for 1,000 kilometers of range – to be refueled in ten to fifteen minutes. Daimler Truck aims to build a supply chain for liquid hydrogen together with Kawasaki Heavy Industries. The companies signed a memorandum of understanding for this in 2024.

As for gaseous hydrogen and buses, Daimler Buses has been cooperating with H2 Mobility Deutschland since 2024. According to Gorbach, only 50 hydrogen refueling stations were available across Europe in 2024. The need, according to Daimler Truck board member Andreas Gorbach, will be 2,000 by 2030. This would require 25 new hydrogen refueling stations to be installed each month.

Some regions and municipalities are also advancing hydrogen infrastructure. Since April 2025, the municipal utility Stadtwerke Stuttgart (SWS) has invested €50 million in the production of green hydrogen at the Stuttgart port, €16.6 million of which is funded by the region, the EU and the Federal State of Baden-Württemberg. Starting in December 2026, 1,200 tonnes of hydrogen per year are to be produced here using electricity from wind and solar power. This fuel will be used to refuel fuel cell-based buses, trucks and inland vessels. The amount corresponds to four million liters of diesel, which would have emitted 15,000 tonnes of CO2. Via seven kilometers of pipelines, which are now being laid along the Neckar River, the hydrogen will be transported from the Green Hydrogen Hub Stuttgart (GH2S) with its four electrolyzers to the respective refueling stations. These are located at the SSB bus depot in Gaisburg, at the Neckar port in Hedelfingen, and at a truck refueling station in Obertürkheim. According to SWS Managing Director Peter Drausnigg, there were five times as many requests for hydrogen as SWS can ultimately supply. In addition, the waste heat generated during electrolysis will be used to supply 1,200 households. The Federal State of Baden-Württemberg is planning two more hubs in the Ulm-Reutlingen and Rhine-Neckar regions.

Operating costs must come down

Starting in 2039, Daimler Truck plans to offer only CO2-neutral commercial vehicles in Europe, the USA and Japan – in line with the agreement with Kawasaki to decarbonize freight transport. Whether this will succeed depends on technology, costs and infrastructure. Daimler Truck already has a battery-electric drive on the market with the eActros 600.

However, both technologies still need to improve in terms of cost. Daimler Truck board member Andreas Gorbach says: “Trucks are capital goods that must pay off over their entire service life.” If the 600-kWh battery alone is already twice as expensive as a diesel powertrain, the ZEV must demonstrate its advantages in operation. In 2024, the cost per kilowatt-hour at the charging station was still €0.70, and hydrogen cost between €10 and €15 per kilogram. Gorbach: “The alternatives become attractive at €0.40 and €4 to €5 respectively.”

© Cellentric / KD Busch.com

Therefore, in the interim, truck tolls and diesel taxes on the one hand, and government subsidies on the other, must offset the price difference. A CO2-based toll must be introduced across Europe, and around 20 percent of the revenue should be invested in the development of charging stations and hydrogen refueling stations, according to a blog post by Gorbach. The automotive executive also says: “In general, mobility must become more expensive because we have to factor in the environmental costs.”