Regionally available biogenic resources such as wood residues and other woody biomass are often used inefficiently as fuel. Yet there are more efficient utilization pathways. The “AblaPyro” project demonstrates how these materials can contribute to the production of hydrogen and climate-neutral CO2 through the scaling and targeted arrangement of already known and existing process steps. To this end, the construction of a demonstration plant was prepared.

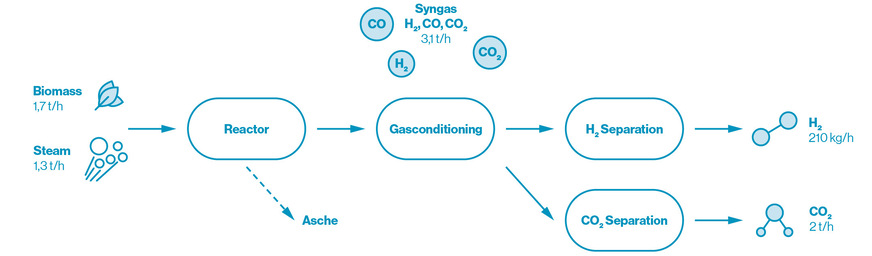

This technology for producing “green molecules” is based on thermochemical gasification in a high-temperature fixed-bed gasifier. In this process, woody biomass is converted into a hydrogen-rich synthesis gas by adding steam at temperatures above 1,000 °C. The synthesis gas is then cleaned and cooled. In a water-gas shift process, the hydrogen content is further increased by converting the carbon monoxide contained in the gas. In the subsequent steps, the CO2 content of the gas is separated and the hydrogen is purified.

H2 for fuel cells, CO2 for the food industry

When designing the process chain for the demonstration project, all process steps required for the operation of the plant as well as the entire necessary peripheral infrastructure were taken into account.

The process includes the following steps:

• Delivery of the various biomass fractions

• Gasification and processing of the resulting products

• Filling of the two resulting

products:

1. Liquefied CO2 in a quality suitable for the food industry.

2. Compressed gaseous hydrogen with a purity suitable for use in fuel cells.

This process chain was classified as innovative and novel by the German Patent and Trademark Office and forms the basis for the granted process patent (DE102024101643B3). In parallel, TÜV SÜD Industrie Service GmbH validated the technical plausibility of the process. The project was planned in Lüneburg, which is part of the Hamburg metropolitan region and has a well-developed infrastructure. For the transformation of fossil energy carriers to produce climate-neutral base or fuels, both hydrogen and CO2 are required. In particular, the chemical industry, the aviation sector, and international shipping face the challenge of defossilizing their required fuels while remaining competitive.

© Bionon

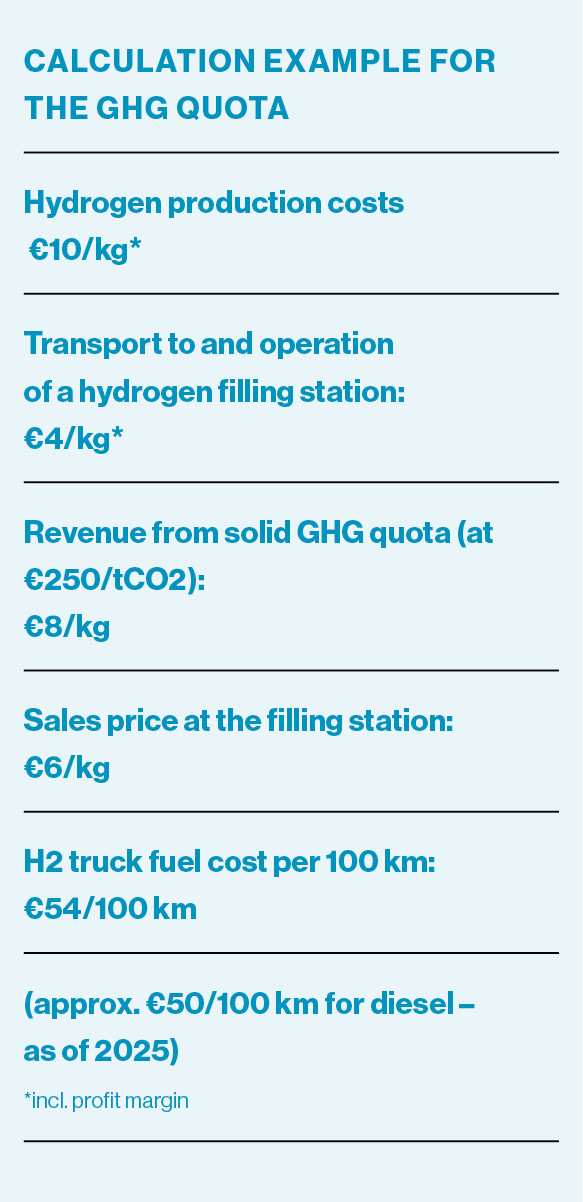

Baseload-capable plant produces hydrogen for €8/kg

The principle of economy of scale was supplemented at an early stage by the influencing factors of biomass availability and the ability to market the produced products at competitive prices. As part of the research project, a production plant was designed to produce 1,600 t/a of biogenic hydrogen and 15,000 t/a of biogenic CO2 from 22,500 t/a of biomass. The plant enables the production of hydrogen at competitive production costs of around eight euros per kilogram and is also baseload-capable. Unlike electrolysis, it does not depend on wind or solar power.

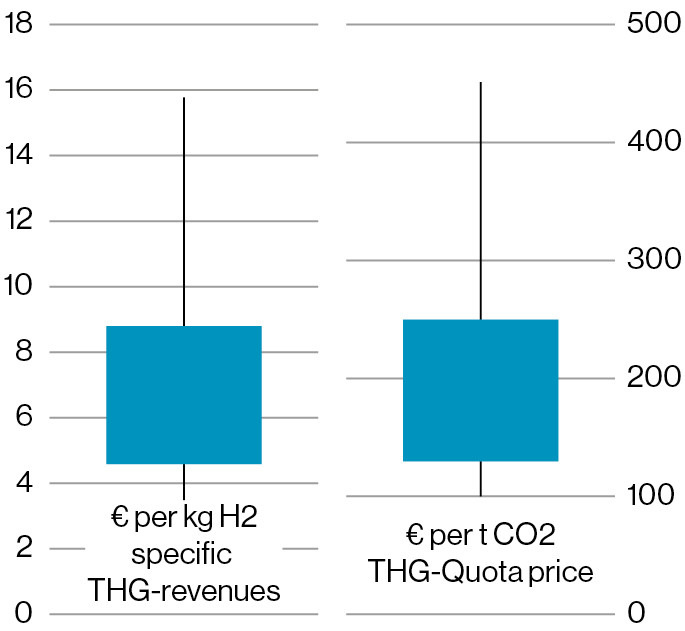

For the economic operation of the plant, trading in greenhouse gas (GHG) certificates (GHG quota) is also important. The biogenic hydrogen produced has negative emissions in the GHG quota system, resulting in additional revenues of three to seven euros per kilogram of hydrogen. Under certain conditions, hydrogen-powered trucks can already be operated today without additional costs using the hydrogen produced. The investment costs for a first-mover demonstration plant amount to just under 55 million euros. Given a calculated profit margin in the clearly double-digit range, the project is attractive to investors.

Für den wirtschaftlichen Betrieb der Anlage ist auch der Handel mit Treibhausgas-Zertifikaten (THG-Quote) wichtig. Der produzierte biogene Wasserstoff verfügt über negativ anzurechnende Emissionen im THG-Quotenhandel, so dass Zusatzerlöse von drei bis sieben Euro pro Kilogramm Wasserstoff entstehen. Unter bestimmten Voraussetzungen können somit bereits heute wasserstoffbetriebene Lkw ohne Zusatzkosten mit dem produzierten Wasserstoff betrieben werden. Die Investitionskosten für eine First-Mover-Demonstrationsanlage belaufen sich auf knapp 55 Millionen Euro. Angesichts einer errechneten Profit-Marge im deutlich zweistelligen Bereich ist das Projekt für Investoren interessant.

The economic results were analyzed and validated as part of a comprehensive due diligence review by EY-Parthenon GmbH Wirtschaftsprüfungsgesellschaft. In addition to the business results for the demonstration project, project partner IfaS (Institute for Applied Material Flow Management at Trier University) also examined the impact of the project on regional value creation. The use of regional biomass, local infrastructure and supply chains in plant operation, as well as the regional use of the hydrogen produced, lead to high regional value creation.

The potential of biomass

The social acceptance of the project was analyzed by the Competence Center for Renewable Energies (CC4E) at HAW and publicly discussed in panel discussions. The biomass used, as well as the electricity used to operate electrolysers, is subject to the strict requirements of the Renewable Energy Directive RED III. This prevents the use of biomass from competing with food production, biodiversity, and sustainability goals. In addition, no additional sources of greenhouse gas emissions may arise from cultivation and harvesting.

Sewage sludge, waste wood, and non-recyclable plastics have passed initial test runs for synthesis gas production and offer a broad, economically attractive field of application for the technology. Another aspect that is still far too often overlooked is the production of climate-neutral, biogenic carbon in the form of CO2. The use of climate-neutral methanol as a basis for fuels in aviation and shipping, as well as for basic chemicals, is becoming increasingly important for climate protection.

Operators of pilot and demonstration plants for the production of hydrogen derivatives are already asking how the required non-fossil carbon for operating their plants can be provided. The sustainable utilization of the biomass used in our demonstration project also includes the industrial use of the carbon it contains.

From feasibility study to implementation

To implement the results developed in the project, a consortium of several companies has been formed: Bionon UG, A.H.T. Syngas N.V., and Bioenergy Concept GmbH. The goal of the consortium is to build and operate a demonstration plant. This is scheduled to go into operation in 2027/2028 and provide the necessary impetus for the hydrogen ramp-up in Lüneburg, enabling the region to develop into a hydrogen economy region. The further implementation of the project could become a win-win-win project for the region, the regional economy, and the participating companies and investors.

© Bionon

![Hydrogen production costs [€/kg]](/sites/default/files/styles/aurora_default/public/aurora/2025/10/486393.jpeg?itok=Bo_yG-DJ)

© Bionon

Biogenic hydrogen

Hydrogen produced from biogenic feedstocks is referred to as “biogenic hydrogen”. From a regulatory perspective, it is classified as an “advanced fuel”.

Possible production methods include biogas or biomethane production, pyrolysis, or biomass gasification.

The biomass to be used is clearly and strictly defined in RED III and in the 38th Federal Immission Control Ordinance (38. BImSchV). This means that cultivated biomass, such as maize, cannot be used. Land use changes due to biomass harvesting are also prevented.

However, residues from forestry and forest-based industries can be used to produce biogenic hydrogen. These include green waste from landscape maintenance, sawdust, and damaged wood. Manure, slurry, nutshells, bagasse (cellulose-rich residues from sugarcane processing), and sewage sludge can also be used.

By capturing and industrially utilizing the contained CO2 (CCU), for example in the production of marine and aviation fuels, biogenic hydrogen can achieve negative greenhouse gas emissions. Due to the increasing demand for climate-neutral fuels for the maritime sector and aviation, as well as for basic chemicals for industry, biogenic CO2 will become increasingly important. In addition to direct air capture (DAC), it offers an additional path to climate neutrality.

Biogenic raw material sources are often not fully utilized today (heat and/or power generation without CO2 utilization). These sources should be fully exploited through material conversion into “green molecules”. Since biogenic hydrogen is produced independently of wind and solar power, it is baseload-capable and available at all times. The established regional infrastructure and supply chains for biomass also strengthen regional value creation.

Utilize instead of neglect!

Biogenic hydrogen, biomethane, and biogenic CO2 must finally receive the political and societal recognition in the energy transition that they deserve. Biomass alone is not sufficient to achieve climate neutrality. However, an energy transition that ignores biogenic processes and products will not be successful.

Strengthen biogenic hydrogen!

Biogenic hydrogen is not to be equated with conventional biofuels. Its production processes are significantly more complex. In addition, the production plants are not yet widely established. Unlike conventional biofuels, the use of biogenic hydrogen does not result in local GHG emissions. The carbon contained in the biomass is captured during the production process and displaces fossil CO2 in industrial processes.

To activate the market for hydrogen and green gases derived from biogenic residues, the following aspects should be considered in the legislative process for implementing RED III:

• Biogenic hydrogen must continue to receive multiple crediting in the GHG quota system.

• The minimum share of biogenic hydrogen (advanced fuel) that must be placed on the market must be increased.

• The scope of application of biogenic hydrogen in the GHG quota system must be extended to all vehicles, not just road vehicles, but also rail and waterborne vehicles

• GHG quotas must be extended at least until 2045.

• Differentiation between biogenic hydrogen and biofuels in their use as marine and aviation fuels, in compliance options, and in the crediting of GHG emissions

To make biogenic hydrogen (and biomethane) competitive with fossil feedstocks, they should receive multiple crediting of GHG savings in industrial material use under the ETS-2 Directive or the Fuel Emissions Trading Act (BEHG).

GHG quota trading: key market instrument for the hydrogen ramp-up

GHG quota trading: key market instrument for the hydrogen ramp-up GHG quota trading enables the economic operation of hydrogen projects without the need to keep production costs low through government investment subsidies. Quota trading leads to additional revenues from the sale of climate-neutral hydrogen and thus lowers sales prices, even with higher production costs. This increases consumer acceptance.This year, 10.6 percent of the energy content of fuels placed on the market must be climate-neutral. Those who do not meet this minimum quota must purchase CO2 certificates through certificate trading. Those who sell more climate-neutral fuels and exceed the minimum quota can sell the excess share in the form of certificates.To meet the quota, the various production methods (e.g. RFNBO, biogenic hydrogen, and biodiesel) are weighted differently. The GHG savings of RFNBO are credited threefold, those of biogenic hydrogen twofold.

By capturing and industrially utilizing the biogenic CO2, negative emissions can be achieved in the production of biogenic hydrogen, resulting in higher GHG savings than with RFNBO. This compensates for the disadvantage of biogenic hydrogen in multiple crediting.In the past, fraud cases led to a collapse in GHG certificate prices. As a result, hydrogen projects became uneconomical, or consumer prices rose to uneconomical levels.In the legislative process for implementing RED III, the loopholes that enabled fraud are now to be closed.To achieve this goal even more effectively, the “Initiative to Stop Climate Fraud” has published a position paper. (https://carbonleaks.de/pressemitteilung-red-iii)

In addition, the GHG legislation process should ensure that all climate-neutral options for activating the hydrogen market are fairly considered based on their emissions:

• Multiple crediting of biogenic hydrogen must continue.

• Biogenic hydrogen should be creditable not only for road vehicles but for the entire transport sector.

• A permanently effective GHG quota of €200 to €250 per ton of CO2 equivalent is essential to provide the planning security needed for climate protection investments.

It is therefore all the more important that RED III and the laws to stabilize the GHG quota are passed quickly and come into force on January 1, 2026.