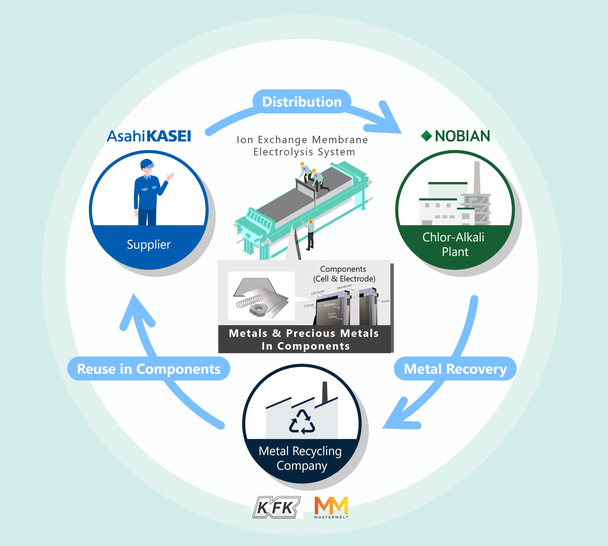

The Japanese technology company Asahi Kasei, together with Nobian, Furuya Metal, and Mastermelt, has initiated a program for the recycling of metals and precious metals. The goal is to recover valuable materials from cells and electrodes used in electrolyzers for the production of caustic soda. Scheduled to begin in February 2025, the initiative seeks to establish a recycling ecosystem for high-value metals in the chlor-alkali industry.

Asahi Kasei has been active in chlor-alkali electrolysis for nearly five decades. The company manufactures ion-exchange membranes, electrolyzer cells, electrodes, and provides operational expertise for electrolyzer plants. In these systems, electrical current is used to split brine into chlorine, hydrogen, and caustic soda.

Precious metals such as iridium and ruthenium are required for the production of electrodes and other components in electrolysis systems. Global demand for these materials is increasing.

Asahi Kasei has already taken several measures to secure its supply of these materials. These include a demonstration project, launched in 2023, for an electrolyzer cell leasing service in Europe, carried out in collaboration with Nobian. This ensures that the cells are returned to the manufacturer at the end of their service life.

The new joint recycling project by Asahi Kasei, Nobian, and recycling specialists Furuya Metal and Mastermelt is designed to establish a circular economy for the chlor-alkali industry. Metals from cells and electrodes that have reached the end of their service life will be processed and reused as raw materials for manufacturing new components.

The recycling process consists of several steps: First, Asahi Kasei collects spent electrodes from Nobian and provides them to Mastermelt and Furuya Metal. These companies remove the catalyst from the electrodes, prepare the material for the next processing step, and extract and purify the precious metals from the catalyst. In the final step, Asahi Kasei uses the recovered precious metals to produce a new catalyst, which is then applied as a coating to new electrodes. Nobian then uses these recycled electrodes to conduct brine electrolysis.

The company is considering applying this process to components in its electrolysis systems for the production of green hydrogen using renewable energy.

The announcement of the recycling project coincides with the planned launch of Asahi Kasei’s AlkaNexus brand at the end of 2024. Designed as an integrated solution for the chlor-alkali industry, the brand combines advanced services in data analytics, plant operation optimization, and membrane technologies.