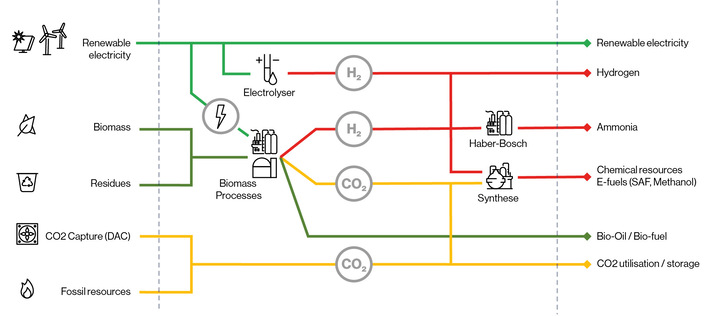

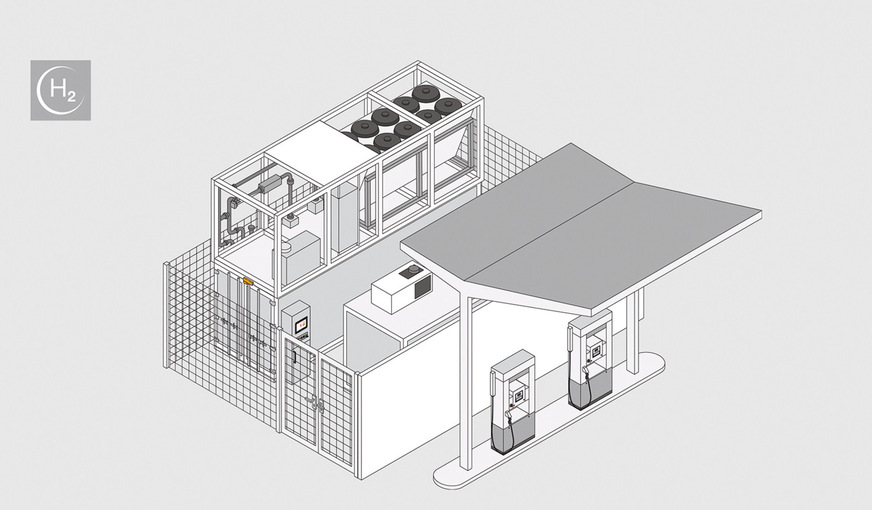

Hydrogen refueling stations require a range of sensors to ensure safe operation. In particular, it is important to reliably detect the temperature and pressure of the hydrogen during the refueling process. Determining the hydrogen concentration in the ambient air is also a safety-relevant measurement. In the future, measuring hydrogen purity could also play an important role.

Kälte- und Systemtechnik GmbH (Kustec) from Austria specializes in cooling systems for hydrogen refueling stations. During refueling, hydrogen heats up as a result of the pressure drop – unlike most other gases. Since the temperature in standard hydrogen tanks is limited to 85 °C, the gas must be cooled before refueling. For monitoring the refueling process, precise sensors are necessary to monitor pressure and temperature. For this, Kustec uses sensors from the Swiss manufacturer Trafag AG, which are suitable for hazardous areas.

A special feature: Trafag's temperature sensors are certified for multiple Ex zones. When designing a hydrogen refueling station, the supplier defines the Ex zones. Previously, it was customary to designate Ex zone 1 at hydrogen refueling stations, says Trafag Managing Director Markus Degasperi. In Ex zone 1, explosive hydrogen-air mixtures can occur during normal operation. Therefore, the sensors must be intrinsically safe, and isolation switches are required in the control cabinet. Today, suppliers try to use zone 2, in which no explosive atmosphere can occur during normal operation, allowing the isolation switches to be omitted. However, to offer suppliers flexibility regarding Ex zones, Trafag sensors are suitable for both zone 1 and zone 2. Trafag offers the temperature sensors in numerous versions. Customers can choose between different measurement technologies and cable assemblies. Kustec uses intrinsically safe temperature sensors with 20 m long cables in its pre-cooling units in the dispensers.

Thin-film-on-steel sensors for pressure measurement

The pressure sensors used by Kustec also come from Trafag. These are thin-film-on-steel sensors. In thin-film pressure measuring cells, several electrical resistors are located on the reverse side of the thin-film membrane, away from the medium, and are connected to form a Wheatstone bridge. Under pressure, the membrane deforms and the resistors are compressed or stretched depending on their position. The resistance changes proportionally to the pressure.

The challenge is to develop a membrane material that is hardly permeable to hydrogen and does not become brittle when in contact with hydrogen. Over time, hydrogen atoms can diffuse through the membrane of a thin-film-on-steel sensor and cause signal drift. Particularly high temperatures intensify the drift.

“What's important is how reliable a sensor is,” says Degasperi. Accuracy and long-term stability are crucial. In particular, the drift of the sensor signal must be prevented. Hydrogen pressure sensors must measure up to 1,000 bar. For releasing the refueling process, they must also be able to reliably detect 0 bar. If the zero point has drifted, there is a problem. “Then it is no longer possible to start,” says Degasperi.

Titanium nitride coating reduces hydrogen diffusion

Signal drift is also an issue for sensor manufacturer Alexander Wiegand (Wika). An external coating with gold can help, as the diffusion coefficient of hydrogen through gold is orders of magnitude lower than through steel. But gold is expensive. In addition, “the front is easily scratched from the outside,” says Christian Wirl, Portfolio Manager Hydrogen at Wika. Every scratch reduces the effect of the gold or even completely eliminates it.

Wika has therefore developed an alternative to gold coating. The company uses a titanium nitride coating only a few nanometers thick to protect the sensor from hydrogen. The sensor body itself is made of the cobalt-chromium-nickel alloy Elgiloy, which is sufficiently elastic. The titanium nitride coating is located on the back of the sensor body between an insulation layer and the actual resistor layer. In this position, the protective layer is shielded from mechanical stress and scratches. The titanium nitride coating also has the advantage of being less expensive than a gold coating. According to Wirl, these pressure sensors can be completely metal-sealed. This eliminates the need for an elastomer seal, which is more permeable to atomic hydrogen than a metal one.

Wika developed and tested the new sensor in its laboratory at its main site in Klingenberg, Germany. The tests showed that the titanium nitride coating prevents signal drift almost as effectively as a gold coating. In terms of robustness, however, the design is said to offer significant advantages and is also suitable for high temperatures. The new technology can be used for pressure sensors with a measuring range from 0 to 1,000 bar. Wika has already started to implement the titanium nitride coating in its end products. The first to feature it are electronic pressure sensors for explosion-proof areas. For temperature measurement, Wika uses thermocouples, which, according to Wirl, are more resistant to pressure and vibration and react more quickly to temperature changes compared to platinum resistance sensors (see H2international 03/2025, page 37).

Vega Grieshaber KG also offers metal thin-film sensors for hydrogen pressure measurement up to 1,000 bar. "We preferably manufacture these measuring cells dry, that is, without oil filling as a transmission medium, to avoid the negative effects of hydrogen diffusion on the oil," says Vega sales engineer Nils Springmann. For its oil-filled metallic measuring cells, the company optionally uses gold or gold-rhodium coatings. Piezoresistive measuring cells with oil filling and gold coating are used in the low-pressure range up to 40 bar. In these sensors, pressure acts on a stainless steel membrane and the oil filling behind it. In the oil, there is a semiconductor element that responds to deformation with a change in resistance. According to Springmann, gold coatings are useful for such piezo sensors. They prevent hydrogen molecules from diffusing through the thin membrane and interfering with the measurement signal.

© iStock.com/Scharfsinn86, Pilz GmbH & Co. KG

Ceramic capacitive pressure measurement for the low-pressure range

For pressures of less than 100 bar, Vega relies on ceramic capacitive measurement. "All measuring points with lower pressures, from 100 bar downwards, we measure using ceramic capacitive technology with a dry ceramic measuring cell. So far, we have had very positive experiences with this," says Springmann. According to Springmann, dry ceramic measuring cells have advantages in terms of robustness and long-term stability. "The leak rates are negligibly small for most applications," says Springmann.

With ceramic capacitive pressure sensors, the pressure acts on a ceramic membrane, resulting in a change in capacitance. The capacitive ceramic sensor works like a plate capacitor. Due to the pressure, the distance between the electrodes decreases and the capacitance increases.

Determining hydrogen purity

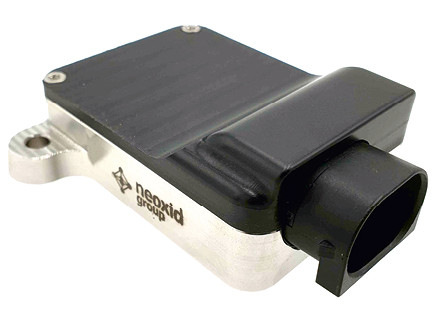

Pressure and temperature are important parameters during hydrogen refueling, but not the only ones. Neoxid Hydrogen AG focuses on sensors for detecting hydrogen purity and hydrogen concentration. The company uses the thermal conductivity of a gas mixture as the measurement parameter. The measurement signal can accurately detect impurities in hydrogen down to the ppm range. The purity of hydrogen is an important factor when the gas is used as fuel in a fuel cell. Impurities such as carbon monoxide or oxides of sulfur or nitrogen act as catalyst poisons and can significantly reduce the performance and service life of the fuel cell. Therefore, hydrogen 3.7 is used for fuel cell drives, which has a purity of more than 99.97%.

At today's refueling stations, which obtain hydrogen from nearby PEM electrolyzers, purity is not a problem, says Neoxid Managing Director Dieter Ostermann. However, this will change as more and more stations source gas from the hydrogen core network. Then it will not be possible without purity sensors. This is because the pipelines, which also include sections repurposed from natural gas operation, must be expected to contain impurities in the range of 1%. Ostermann expects that sensors will be installed in cars to stop the refueling process if the quality is not right. But purity sensors will also become unavoidable in the stations themselves.

According to Ostermann, Neoxid is the only supplier that can measure hydrogen concentration in operation at high pressures without complex sample preparation and measurement in a gas chromatograph. The measurement of thermal conductivity does not change the gas composition and the measurement signal is compensated for pressure, temperature, and humidity. This allows the proportion of water vapor to be distinguished from other impurities.

Sensors for hydrogen concentration in the air

Another application for Neoxid sensors is measuring hydrogen concentration in the air. Gas warning devices can use them to detect leaks and warn of explosive hydrogen-air mixtures. For this application, not only is thermal conductivity measurement suitable. Usually, pellistors are used, which are based on the principle of catalytic combustion. In the sensor, hydrogen burns and, depending on the concentration, generates an additional amount of heat that can be detected. The electronics evaluate the temperature change at the sensor surface and determine a gas concentration from it. The sensitivity of pellistors reaches below 5% of the lower explosive limit. According to the Fraunhofer Institute for Physical Measurement Techniques IPM, the advantages of catalytic sensors lie in their simple operating principle, uncomplicated installation, and reliable calibration. However, modern pellistors also have some disadvantages. Above all, high operating temperatures, high power consumption, and susceptibility to catalyst poisons have a negative impact.

© Pilz GmbH & Co. KG

Control systems use sensor signals for error detection

Accurate sensors that reliably record the actual state are one thing. The other are control systems that detect errors and react automatically based on the measured values. Pilz supplies control systems that detect gas leaks by analyzing gas detectors and monitor temperature, pressure, fill level, voltage, and current. They detect errors in the millisecond range and initiate predefined safety responses if the limit values for filling and emptying set by the hydrogen tank manufacturer are not met. If malfunctions occur during refueling of a vehicle, the control system switches an electronic safety valve to, for example, trigger an emergency stop of the process or reduce the power of a compressor.

The Pilz control system monitors the critical limit values for pressure, temperature, and the hydrogen charging and discharging rates. It also analyzes the pressure gradient to detect anomalies or errors at an early stage. A rapid drop in pressure can indicate leaks. The safety system achieves an accuracy of 1%. If it monitors the pressure range of a hydrogen refueling station from 0 to 1,000 bar, the measurement deviation is 10 bar. According to Pilz, this enables compliance with safety level SIL 3 in accordance with IEC 62061.

In addition to monitoring pressure and temperature during the refueling process, hydrogen refueling stations also require the detection of hydrogen leaks, flames, and smoke. The monitoring system from Pilz is already used at several stations in France.

An important aspect of control systems is cybersecurity. Unauthorized access to control systems in the hydrogen sector can pose a major safety risk. Pilz therefore also offers systems for access and authorization management, which support data and network security, user authentication, and access management.

This ensures that, through the interaction of sensor technology and monitoring electronics, both people and hydrogen installations are well protected.