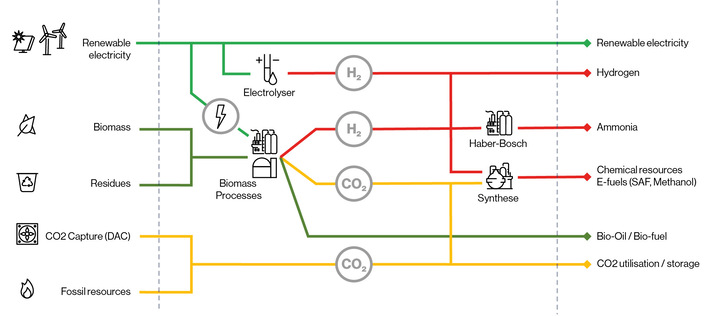

The H2 reference factory, coordinated by the Fraunhofer Institute for Machine Tools and Forming Technology (IWU), is fully operational following the completion of the H2GO and FRHY projects. The platform's goal is to enable the industrial series production of electrolysers and fuel cells, significantly lowering manufacturing costs. The H2GO and FRHY projects focused on developing production systems for fuel cells in heavy-duty mobility and for electrolysers.

New processes for key components

The H2 reference factory is located in the research factory of the Fraunhofer IWU and is understood as a value creation community of several Fraunhofer institutes and industry partners. It covers the entire production chain—from product development to series production. It employs a roll-to-roll process, allowing uninterrupted material processing and enabling high production rates with low unit costs.

A focus is on the production of bipolar plates, which are central components in both fuel cells and electrolysers. Here, the H2 reference factory uses hollow embossing rolling. This continuous process reduces process forces by a factor of ten compared to traditional pressing methods, allowing for smaller and more cost-effective equipment.

Goal: Scalable production for reducing costs

With the now available infrastructure, Fraunhofer IWU aims to create the conditions for scalable and economical production of hydrogen systems. The reference factory is intended to serve as a blueprint for industrial production lines and to facilitate companies' entry into series production.

"Prices must come down," states the institute's announcement. Only then can a wide availability of electrolysers and fuel cells be achieved, making a significant contribution to CO₂ reduction.