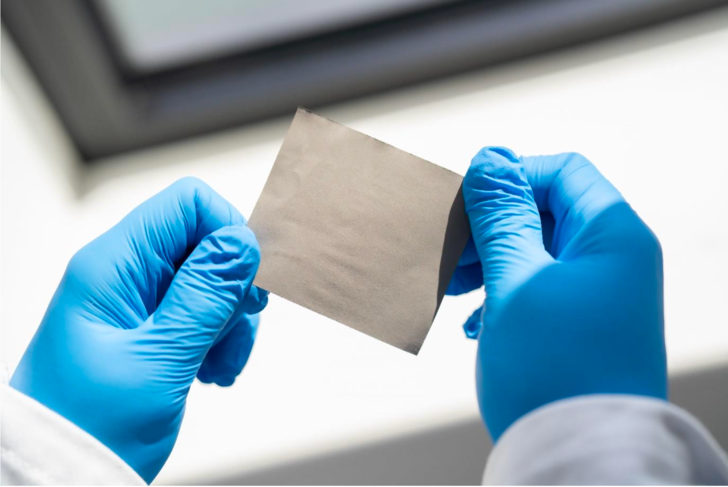

M-Spin, a London-based company specializing in materials technology, has introduced a novel metallic support material for electrochemical applications. The so-called nanofiber-based metal meshes consist of fibers with diameters ranging from 500 nanometers to 1 micrometer and achieve a porosity of up to 90 percent. As a result, they offer a surface area more than 1,000 times greater than that of conventional metallic foams.

According to the company, the meshes enable up to five times higher production rates in water electrolysis and improve efficiency by around ten percent. Overall, this could reduce the cost of green hydrogen by approximately 20 percent.

According to M-Spin, the meshes can be mechanically processed and integrated into existing cell architectures. They could serve as a high-performance replacement for conventional current collectors and porous metals.

Scalable production and customizable properties

Production is based on a patented process that allows for a wide range of materials – including nickel, iron, copper, as well as alloys and ceramics. Structural parameters such as fiber size and pore geometry can be tailored to specific applications. According to M-Spin, the production process is cost-efficient, generates little waste, and is scalable for high volumes.

M-Spin is a spin-off from the environment of Imperial College London. The company positions itself as a provider of high-performance materials for electrochemical energy systems and aims to contribute to cost reduction and efficiency improvement in the hydrogen economy.