As part of the Mid-West Green Iron project in the Geraldton region (Western Australia), PGS plans to produce up to seven million tonnes of green iron pellets annually. Around 2.5 million tonnes of these are to be further processed into hot briquetted iron (HBI). The plant is to be powered entirely by locally generated renewable energy and will use green hydrogen produced with electrolyzers from Thyssenkrupp Nucera. However, the naming does not yet imply a binding order. The entire front-end engineering and design (FEED) process is still pending, as is the final investment decision (FID). In addition, PGS is not an established steel or industrial group, but a developer of large-scale green projects in the fields of steel, energy and ammonia. No information on investors or a financing structure can be found on the company’s website.

Megaproject for green iron

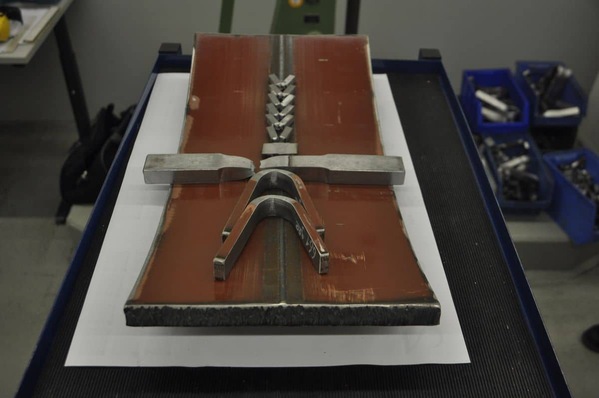

PGS aims to produce two types of iron products using green hydrogen and local magnetite iron ore. One is pellets made from direct reduced iron (DRI). In this process, hydrogen removes the oxygen from the iron oxide pellets, making them light and porous. To facilitate transport, PGS also plans to produce briquettes from them, known as hot briquetted iron (HBI), which resemble charcoal briquettes used for barbecuing. CO2 emissions are expected to be reduced by up to 90 percent compared to conventional production methods. In the long term, PGS plans to increase production capacity to up to 30 million tonnes of pellets and 10 million tonnes of HBI per year.

Standardized 20 megawatt modules of Thyssenkrupp Nucera’s Scalum technology are to be used. The electrolyzers are based on alkaline water electrolysis.

If everything goes according to plan, the first iron could be exported in 2029. Thyssenkrupp Nucera intends to further develop the project together with PGS and initially conclude an EPF contract (engineering, procurement, fabrication). Impacts on the company’s revenue and earnings are not expected before the 2026/27 fiscal year. PGS Managing Director James Rhee emphasized: “We appreciate the efforts and expertise that the team at Thyssenkrupp Nucera Australia has contributed to our pioneering green iron project so far.”

With the PGS project, the total capacity of projects for which Thyssenkrupp Nucera is designated as the preferred technology supplier rises to over 3 GW. The company, headquartered in Dortmund, is one of the leading providers of electrolysis technologies and has implemented more than 600 projects worldwide with a total capacity of over 10 GW.