It is not easy to concentrate on the PowerPoint presentation in Bürkert’s conference room. Anyone interested in the manufacture of measurement, control and regulation components can see far more through the large glass wall. The view sweeps across a modern factory floor. From above, the most striking features are the glazed work areas where people sit at computer workstations. Using Bürkert valves, sensors and controllers, they design complete assemblies and solutions tailored specifically to individual customer requirements. “We call this place the Systemhaus,” says Dominik Fröhlich, responsible for Bürkert’s business development for energy sector customers in Germany, Austria and Switzerland.

For the company, whose history began 80 years ago with solenoid valves and which today also manufactures sensors and controllers, the hydrogen sector is one of four target industries. “We see the energy market – hydrogen in particular – as a clear future market with significant growth potential,” Fröhlich adds.

A solution from the Systemhaus might, for example, combine a Siemens PLC control unit with a Bürkert valve terminal. The latter translates electrical control signals into compressed air to actuate the pneumatic valves. The entire assembly is not only designed for the ATEX zone often specified by customers, but can also be deployed in functionally safe installations.

According to Fröhlich, this high level of integration is particularly attractive for electrolysis plants in the hydrogen sector. Understanding customer requirements and working together in a spirit of trust is a distinctive strength, he says. This close technical relationship with customers is how the company sets itself apart from global competitors. Another decisive factor is the continuous investment in developing the portfolio for these applications, reinforcing the company’s leading position in the industry.

One source for everything

For electrolysers, Bürkert aims to score as a one-stop shop. “A 100 megawatt electrolyser contains several hundred control valves, ball valves and butterfly valves, plus roughly the same number of sensors again,” says Fröhlich. Each component has interfaces in the system – not just in the physical sense – and must be specified, ordered, inspected and, in some cases, maintained. “The sheer number of components and interfaces is a challenge for any company. Especially for start-ups whose focus and specialist expertise lie in particular electrolysis technologies, our concept can be a major support,” Fröhlich explains. After delivery, the portfolio optionally includes maintenance services such as seal replacement or calibration – even if the plant contains products from other manufacturers.

Keeping it sealed

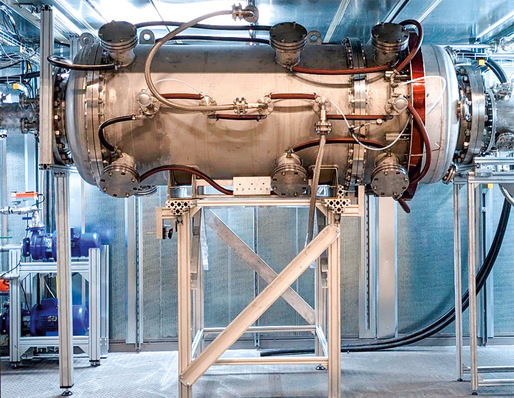

Hydrogen as a medium is nothing new for the company. Bürkert components have been in use in some applications involving the fugitive gas for 25 years. The fundamental requirements are therefore well understood. Yet a few adaptations were still needed for modern applications. Electrolysers and hydrogen refuelling stations in particular operate at very high pressures – several hundred bar in many places. Bürkert had to optimise its portfolio for this, adapting sealing materials in particular and re-testing them under these special conditions. “Our components are designed for the entire service life of an electrolyser,” says Fröhlich. Even in demanding applications such as alkaline electrolysers, where aggressive media like potassium hydroxide (KOH) are used, Bürkert offers an optimised portfolio that reliably handles these conditions. This ensures that the company’s solutions remain durable and high-performing even under extreme demands. “Because we understand the requirements, we can not only supply the right components but also provide the service to go with them,” Fröhlich says.

© Bürkert

Components for niche applications and beyond

Bürkert can justifiably claim to have the right fluidic solution for virtually any application – a result of the company’s strategy. The fluidics experts, headquartered in Ingelfingen, place a strong emphasis on system solutions. By skilfully selecting from the standard range of individual valves, sensors and controllers, they create new system solutions matched to specific requirements.

The components and system solutions are often assembled by hand at dedicated workstations. The experienced assembly team, many of whom draw on decades of expertise, carries out the defined assembly steps with precision. Staff are supported by state-of-the-art technology. Parts for individual components travel from the high-bay warehouse in transport boxes along roller conveyors beneath the hall ceiling and via lifts to arrive almost directly at the respective assembly station. A monitor at each workstation displays which product is to be assembled and what needs to be observed. Some assembly stations also have robots to assist the operators.

Bürkert is also prepared for potential future large-scale series production, as the Gerabronn production site demonstrates. There, the company already manufactures coils and valve components on production lines designed for high volumes. Should the hydrogen industry continue to grow and scaling of valve production become necessary, nothing stands in the way. Fröhlich says: “We expect the industry to take off in the 2030s.”