The new XTI rupture disc from Bormann & Neupert by BS&B is milled from solid material and manufactured entirely without weld seams. This is designed to ensure particularly good leak-tightness in high-pressure applications.

Weld seams found on some rupture discs also represent a potential weak point during operation. According to BS&B, the integrated design of the XTI therefore eliminates joints entirely. This is intended to offer plant operators absolute leak-tightness and high process reliability. It also eliminates the need for weld inspections and documentation, simplifying the technical approval of systems.

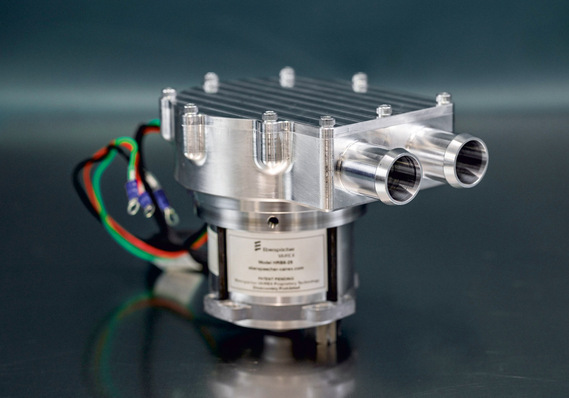

In addition, the XTI rupture disc is very compact and lightweight, making it suitable for mobile applications or installation in confined spaces.

Continuous operating pressure of up to 80 percent of the minimum burst pressure is possible without increased risk, as is use in vacuum conditions or with frequently changing pressure cycles. The disc responds with high precision when the critical pressure is reached, BS&B states. The cross-scored design also prevents fragments from being released – an important safety feature. The XTI rupture discs are also maintenance-free and meet the relevant safety standards, such as the Pressure Equipment Directive.

BS&B manufactures the discs to customer specifications “in all common materials” and in diameters from 0.25 to 1 inch, with customised process connections. Small quantities or one-off production runs are also possible. Delivery is ready-to-use, fully assembled and operational.

More information: bormann-neupertbsb.de