Greene Tweed has introduced a new compressor technology for hydrogen pipelines. The closed impeller made from composite materials achieved a tip speed of 688 m/s in tests – twice that of conventional metallic impellers, according to the company.

Transporting hydrogen by pipeline requires high-performance centrifugal compressors to maintain system pressure. However, tip speed is limited by the material, which in extreme cases could burst under excessive load. According to Greene Tweed, metallic impellers reach 360 m/s in closed designs and up to 500 m/s in open designs. With light gases such as hydrogen, this is insufficient to achieve the desired compression ratio, meaning additional compression stages are required. This takes up space and adds costs for procurement and maintenance.

With the EU’s current plans envisaging tens of thousands of kilometres of pipelines by 2040, cost-

effective, durable high-speed compressor technologies are needed. Composite materials offer significant potential in this regard.

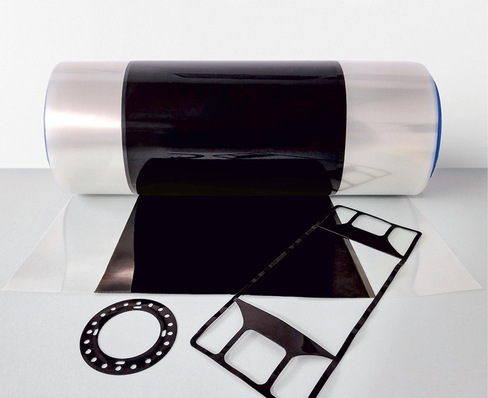

Greene Tweed says it has been working on the new impeller since 2020. The company uses carbon fibre-reinforced polyetheretherketone

(C/PEEK) due to its high specific strength and temperature resistance. The target was a tip speed of over 600 m/s, which has now been exceeded after three development and testing cycles.

According to Greene Tweed, the new impeller weighs only around one fifth as much as metallic impellers and is said to have three times the strength-to-weight ratio.

The technology is also highly scalable. Greene Tweed is currently working with centrifugal compressor manufacturers (OEMs) to bring the new technology to industrial applications.

Greene Tweed manufactures high-performance thermoplastics, composite materials, sealing systems and engineered components for specialised applications. Customers of the 160-year-old company come from the semiconductor industry, oil and gas, aerospace, defence, and the chemical and pharmaceutical process industries.

More information: www.gtweed.com