Agfa and the Flemish research institute VITO have entered into a long-term cooperation to further develop membranes for alkaline water electrolysis. A new production facility for ZIRFON membranes is expected to support up to 20 GW of electrolysis capacity per year.

The aim of the partnership is the joint development of next-generation membranes that are intended to increase the efficiency of electrolyzers and reduce the production costs of green hydrogen. The focus is on advanced porous membranes which, according to VITO, are expected to enable higher performance and scalability. The agreement was signed in the presence of the Flemish Minister-President Matthias Diependaele at the Agfa facility in Mortsel, Belgium.

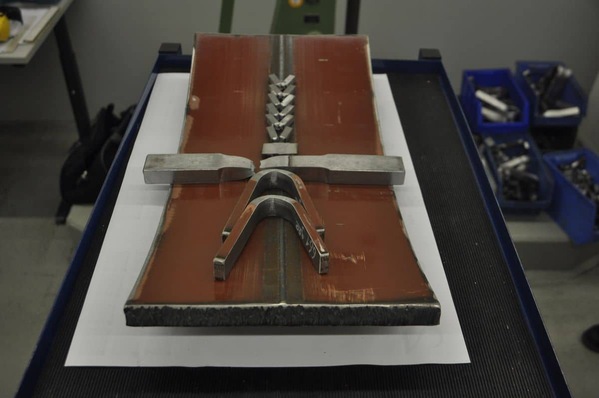

ZIRFON membranes for dynamic operating conditions

Agfa has been producing ZIRFON membranes for several years. These are used as separators in alkaline electrolyzers and are considered particularly high-performing under dynamic operating conditions, such as those encountered when using renewable energy sources. The new production facility in Mortsel, which is scheduled to open later this year, is expected to significantly increase capacity.

According to the company, the new facility is supported by the EU Innovation Fund and is expected to enable a production capacity that supports up to 20 GW of electrolysis capacity per year. This could help avoid up to 15 million metric tons of CO2 emissions annually. The facility is intended to supply the global market for industrial green hydrogen projects.

A Combination of scientific expertise and industrial knowledge

Agfa and VITO have been working together on the development of ZIRFON membranes since 2007. Vincent Wille, President of the Digital Printing Solutions & Chemicals division at Agfa, stated: “Our joint roadmap with VITO, combined with our new production capacity, will significantly accelerate the transition to a radically more environmentally friendly world.”

Inge Neven, CEO of VITO, also emphasized the importance of the cooperation: “Together, our two organizations combine scientific expertise and industrial knowledge to deliver concrete solutions for a climate-neutral future.”