The South Korean chemical company Kumho Mitsui Chemicals (KMCI) has commissioned a new chlor-alkali plant at its Yeosu site. The plant is based on the e-BiTAC v7 electrolyzer technology from thyssenkrupp Nucera. It has a production capacity of 60,000 tons of chlorine per year.

According to KMCI, the new plant will help to reduce dependence on imported chlorine. The chlorine produced will be used in the production of methylene diphenyl diisocyanate (MDI) - a key raw material for polyurethane products such as TPU, artificial leather, paints and adhesives.

A technical feature of the plant is the recovery of thin brine, which is a by-product of MDI production. This is fed back into the process instead of being disposed of as waste water. According to KMCI, this enables it to meet environmental requirements more efficiently and improve its environmental footprint.

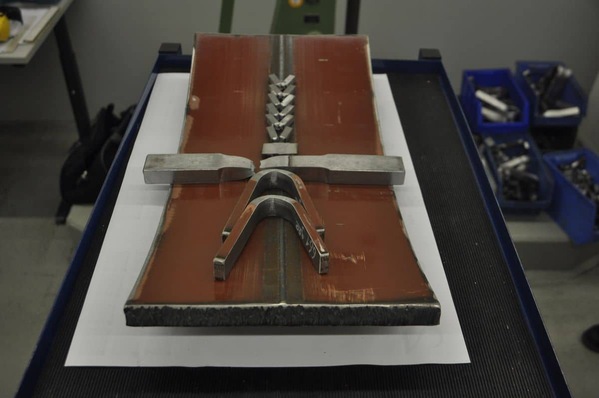

Thyssenkrupp Nucera initially supplied a laboratory cell as a pilot plant to test the technical feasibility of operating with thin brine. Following successful testing, the company was awarded the contract for the planning and delivery of the entire plant in 2021.

“By recovering thin brine as a by-product, KMCI and Thyssenkrupp Nucera have jointly addressed one of the most important issues in the polyurethane industry,” says Akira Shigeta, CEO of Thyssenkrupp Nucera Japan.

Thyssenkrupp Nucera specializes in technologies for large-scale electrochemical plants. The company has realized more than 600 projects worldwide with a total output of over 10 gigawatts. The company's chlor-alkali electrolyzers are designed for fast and cost-efficient installation.