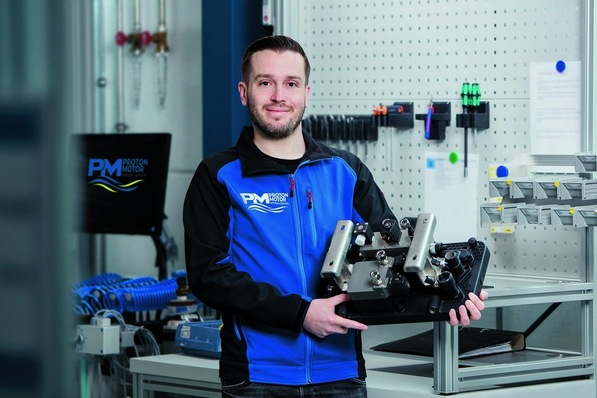

The Fraunhofer Institute for Laser Technology (ILT), together with iGas energy and the manufacturing specialist dLS LichtSchneiderei, is developing new methods for the production of PEM electrolysers. The focus is on eliminating costly precious metal coatings by using laser-welded titanium expanded metal with high electrical conductivity. The project, titled “AI-supported welding and cutting of expanded metal for efficient electrolyser production” (KISSSEs), started in October 2025 and is scheduled for three years.

Researchers at Fraunhofer ILT are relying on artificial intelligence (AI) to identify optimal welding points in complex lattice structures. This precise welding reduces electrical contact resistance and makes expensive precious metal coatings unnecessary. Additionally, AI-supported laser cutting processes improve the edge quality of the grids, which is expected to further increase the efficiency of the electrolysers.

“Our AI models identify the optimal welding points even in irregular expanded metal geometries, enabling reproducible contacts with lower resistance,” explains Zhiheng Ye, hydrogen expert at Fraunhofer ILT. “This lays the foundation for scalable and resource-efficient electrolyser production.”

The project focuses on proton exchange membrane electrolysis (PEM), where a membrane electrochemically separates water into hydrogen and oxygen. PEM systems are considered particularly suitable for operation with fluctuating renewable energies, as they offer high power density, short response times, and good partial load capability.

The PEM stacks used in the project are supplied by iGas energy. They produce up to 260 normal cubic meters of hydrogen per hour and can be scaled by coupling. iGas energy also contributes electrochemical system expertise, develops flow and cell models, and tests the components in operation.