As part of the market overview that H2-international published in the January 2022 issue, we asked manufacturers about improvements and changes over the preceding 24 months. The presented developments revealed that all the suppliers have made significant progress and are well on the way to establishing an electrolyzer market.

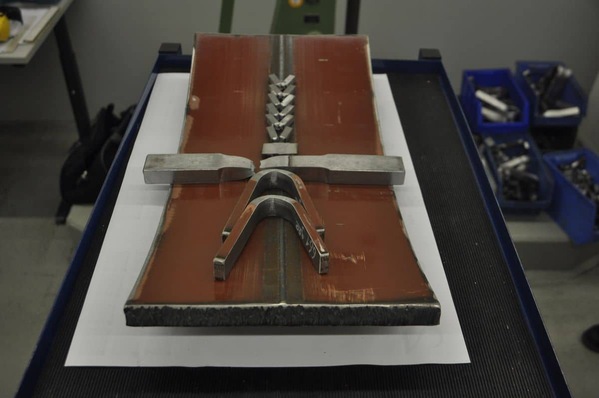

For example, H2V reported that their energy requirement for H2 generation (kWh per Nm3H2) was able to be significantly reduced. H2 Core Systems succeeded in reducing costs by 30 percent just from a switch to series production. Through F&E measures and process optimizations of its own, the partner company Enapter, in the model change from EL 2.0 to EL 2.1, reduced the size of its electrolyzer by 4.5 cm, which was accompanied by a five percent reduction in energy consumption. Meanwhile, EL 4.0 came into being as the the fourth generation of the patented and ISO 22734 certified AEM (anion-exchange membrane) electrolyzer. In March 2022, so before the official market launch this summer, more than 400 orders had been placed.

Sebastian-Justus Schmidt, cofounder and CEO of Enapter, said, “The EL 4.0 will be a building block for system integrators that will allow them to quickly introduce H2 production and realize the necessary global market ramp-up. We are certain that the future mass production of these AEM electrolyzers will fundamentally change the production of green hydrogen.” Mass production of more than 10,000 modules per month is to take place next year at the site currently under construction in Saerbeck, Germany.

Author: Sven Geitmann