At Hannover Messe 2022, the high-speed stacker from VAF was presented for the first time. It enables the production of up to 70,000 stacks per year and thus set new standards for large-scale manufacturing of PEM fuel cell stacks. Since then, VAF has continuously optimized and further developed the performance of the system with customers from around the world for every new project. The core components are the patented stacking process and the workpiece carrier adapted for each product. This makes the process flexible and suitable for many products.

Components are aligned against a stop

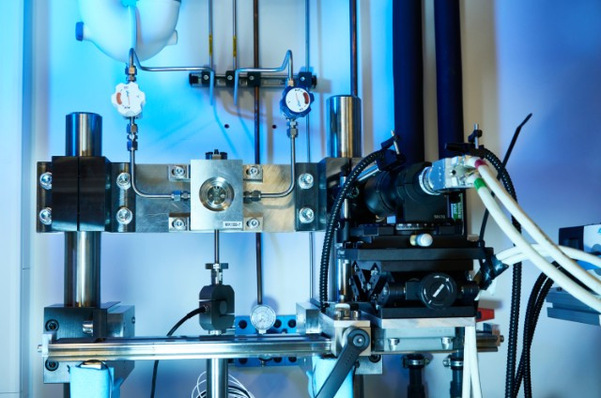

The cell components are precisely mechanically aligned in the workpiece carrier by being positioned against a fixed stop using a patented push technology – similar to how you align a stack of paper by tapping the edges on a desk. This achieves the required accuracy. The challenge of this process lies in executing it in such a way that no damage occurs. This can only be achieved through precise process optimization and the appropriate selection of materials for the parts that come into contact with the workpiece.

As a result, it becomes possible to achieve higher speeds in the upstream pick-and-place process, since the robot does not have to position the cell components as precisely.

Gripping technology limits the speed

High demands are placed on gripping technology in both electrolyzer and fuel cell manufacturing. For the high-speed stacker, VAF uses flow grippers that pick up the cell components using vacuum. These are specially adapted to the components. However, it is also a matter of using the right process parameters to determine whether and how the grippers function. Factors such as holding times during pick-up, the suction power of the gripper, and the behavior of the component determine the cycle time.

Challenging are the increasingly larger cell areas and thus larger and heavier components that come with advancing technology. Their inertia makes these highly dynamic processes more difficult. A low weight of the gripper therefore has a positive effect on the processes. At the same time, the gripper must retain a certain stiffness, since some membrane electrode assemblies are floppy and the outer contours are delicate. In order to place such components precisely, the gripping technology and process parameters must be finely tuned.

Basically, this technology developed for PEM stacks could also be transferred to other types of fuel cells, but PEM technology receives the most attention due to automotive applications.

Between special-purpose machines and series production

The main advantage of a special-purpose machine is that the system is fully adapted to customer requirements. However, completely new systems always involve a risk, and only after completion is the system’s functionality proven. In highly dynamic processes such as stack production, the risk is significantly higher that issues will only become apparent afterwards. In addition, new designs are considerably more expensive than systems that can be built multiple times. Therefore, the high-speed stacker is a combination of both. The basic concept of the systems is the same. Only the key elements – such as the gripping process and the workpiece carrier – are customized for each case. In addition, VAF offers its customers the possibility to carry out comprehensive test series in advance on its own pilot plant and to incorporate the information gained into the customization of the customer’s system. This saves engineering hours and at the same time reduces risk.

Electrolyzers are more specialized

The stacking process for electrolyzers differs in several respects from that for a fuel cell. Most fuel cells now consist of a maximum of two different components – the membrane electrode assemblies and the bipolar plates. In electrolyzers, the components are more varied, larger in area, and often more challenging in geometry for automation.

Electrolyzer manufacturing is not yet as advanced in scaling as fuel cell manufacturing. As a result, the requirements for the systems are in other areas. The entire system is larger due to the outer dimensions of the components. Due to the higher variety of cell designs, the different materials, and the tight tolerances, the demands on the stacking concept and the innovative gripper are high. Even small adjustments to the cell design can significantly reduce the complexity of the systems and thus lower costs accordingly. The experience gained from building the first systems for stack assembly can be used for many concepts and processes in the next generations of systems.

Close cooperation is necessary

The reputation for reliability, durability, and precision continues to give German mechanical engineering companies an advantage, especially in fuel cell and electrolyzer production. However, increasing competition from Asia is clearly noticeable. This leads not only to strong price pressure but also to technical competition at a high level.

However, German companies can score with their trustworthy cooperation. Stack manufacturers maintain close exchanges with mechanical engineers regarding their technologies. The aim is to develop tailored solutions for production and to optimize products in order to reduce the complexity of the machines and the costs. This approach is based on a solid foundation of trust, as the manufacturers must disclose extensive expertise for the machine builders to find and provide innovative solutions. This exchange has contributed to the machines achieving a high level of process stability and meeting quality requirements, so that stack manufacturers receive a reliable production line.