Asahi Kasei has received the 2025 Imperial Invention Prize from the Japan Institute of Invention and Innovation for this new process—according to the company, the highest national award for technological innovation. Chlor-alkali electrolyzers featuring the new coating are already in use by chemical manufacturers around the world. According to Asahi Kasei, chlor-alkali electrolyzers are currently operating in over 160 facilities across approximately 30 countries. However, hydrogen production plays only a minor role in this context. Chlorine is primarily used in large volumes for the production of PVC, epoxy resins, and solvents. Caustic soda (sodium hydroxide) is required for processes such as bauxite digestion in aluminum production, paper manufacturing, and the production of soaps and cleaning agents. Asahi Kasei states that it is currently evaluating whether the technology can be transferred to other electrolysis processes—particularly alkaline electrolysis for the production of green hydrogen.

Protective layer for the cathode

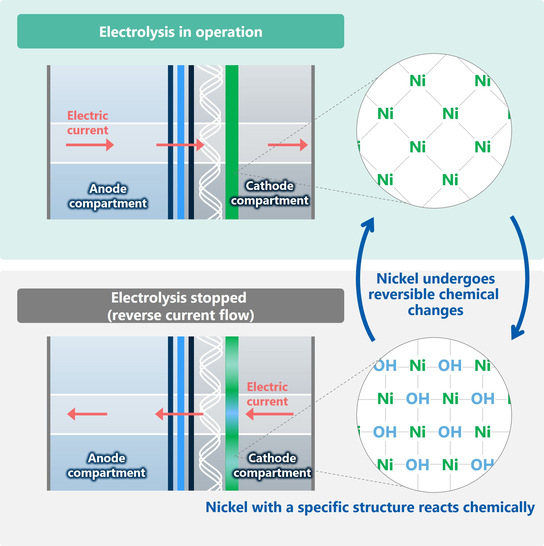

The award-winning innovation addresses a key challenge in chlor-alkali electrolysis: when the electrolysis process is interrupted—due to reduced demand, equipment malfunction, or power outage—the electrodes age more rapidly as a result of reverse current. This leads to increased power consumption and reduced service life, especially for the cathode. Conventional approaches have relied on mechanical solutions to suppress such reverse currents. However, according to Asahi Kasei’s press release, these methods are prone to malfunction and operator error, making it difficult to fully prevent accelerated cathode degradation.

As an alternative to mechanical solutions, Asahi Kasei has developed a reverse-current absorption layer featuring a nickel coating. When the electrolysis process is halted, this layer undergoes a chemical reaction with the nickel, thereby preventing cathode degradation. According to Asahi Kasei, the nickel-coated reverse-current absorption layer is highly porous, mechanically robust, and suitable for application over large surface areas.