As part of the H2Rollout research project, the Westphalian University of Applied Sciences, the company Zinq, and ProPuls GmbH are testing the use of hydrogen in industrial flat flame burners. These burners are used in batch hot-dip galvanizing and are to be fully operated with hydrogen in the future.

Pilot Plant in Castrop-Rauxel Examines Hydrogen Flame in Galvanizing Process

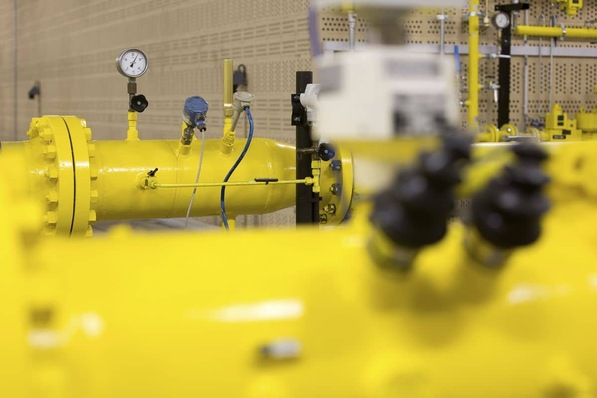

The pilot plant is located at the Zinq site in the city of Castrop-Rauxel, which is part of the Rhine-Ruhr metropolitan region. There, an existing natural gas burner was replaced with a hydrogen-powered variant and integrated into the existing control system. The project's aim is to achieve a 100 percent hydrogen share in the galvanizing process. The focus is on the effects on the galvanizing kettle, the exhaust gas composition, and the overall efficiency.

The conversion is technically demanding, as the liquid zinc tolerates only slight temperature fluctuations. "The challenge is to keep the combustion consistently stable and to integrate it into the existing process," says Martin Habermehl, professor at the Westphalian University of Applied Sciences. His team is responsible for flow simulations and the analysis of the trial operation.

Control Technology Adapted to Hydrogen Flame

ProPuls GmbH, a spin-off of the Westphalian University of Applied Sciences, is developing the control technology for the new burner operation in the project. "The data from the simulations and the measurements from the pilot operation are our basis for optimizing the process control," explains Philipp Neuhaus, team leader for MSR technology at ProPuls.

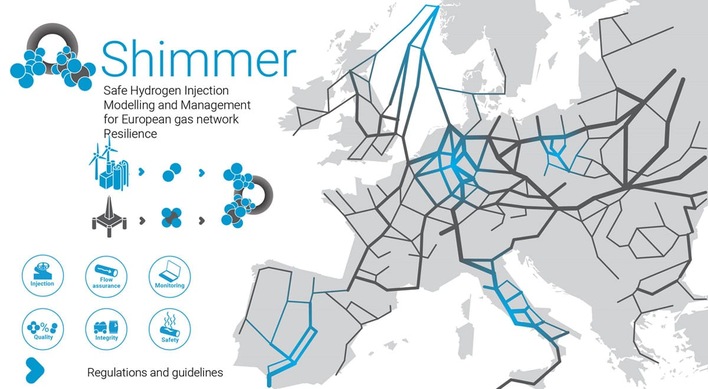

In parallel, Zinq is examining possibilities for a long-term and economical supply of hydrogen. "It lays the foundation for us to be technically prepared once the conditions for the use of hydrogen are established," says Robert Mill, head of plant engineering at Zinq. However, it is crucial that regulatory and economic conditions are also met.

Blueprint for Low-CO₂ Process Heat

The project is funded under the "T!Raum – TransferSpaces for the Future of Regions" program by the Federal Ministry of Education and Research until 2028. It is part of the H2Space initiative (H2Raum in German), initiated by the Westphalian University of Applied Sciences and the Fraunhofer Institute for Energy Infrastructures and Geothermal Energy (IEG). The project partners aim to develop a transferable solution for the galvanizing industry and other process heat-intensive sectors with the results.

The Westphalian University of Applied Sciences has been researching hydrogen technology for over 20 years. Since the winter semester of 2024/25, it has been offering the course "Hydrogen Systems and Renewable Energies." With the emerging "H2 Solution Lab" in Gelsenkirchen, the location is to be further strengthened.