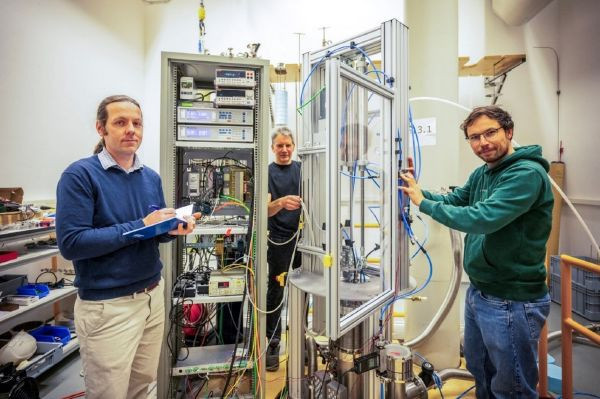

As part of the EU-funded HyLICAL project, the Helmholtz-Zentrum Dresden-Rossendorf (HZDR) and the start-up Magnotherm have developed a demonstration plant for hydrogen liquefaction. The pilot plant uses the magnetocaloric effect, in which certain materials – such as lanthanum-iron-silicon alloys – undergo a temperature change when exposed to a magnetic field. This allows hydrogen, after pre-cooling with liquid nitrogen, to be brought to -253 degrees Celsius and liquefied.

The core of the plant is a 19-tesla superconducting magnet installed at the Dresden High Magnetic Field Laboratory (HLD) of HZDR. For comparison: magnetic resonance imaging scanners in medicine operate with magnetic fields of 1.5 to 3 tesla. “With this plant, we can now demonstrate the principle and how it works,” says HZDR scientist Tino Gottschall. The goal is to increase efficiency to the point where 100 kilograms of liquid hydrogen can be produced per day. In the long term, the team is aiming for an industrial-scale plant with a capacity of 5,000 kilograms per day.

Cost reduction in liquefaction targeted

The project partners aim to significantly reduce the cost of hydrogen liquefaction with this technology. “With the Magnotherm Joint Lab at HZDR, we want to reduce liquefaction costs to below 1.50 euros per kilogram of hydrogen – compared to conventional plants,” explains Gottschall. Conventional processes use energy-intensive compressors and refrigerants that are often harmful to the climate. Magnetocaloric cooling does not require these.

“Our magnetic cooling technology is a climate-friendly and energy-efficient alternative – without compressors and environmentally harmful refrigerants,” says Timur Sirman, Co-Managing Director of Magnotherm. The technology could contribute to the transformation of refrigeration technology.

HyLICAL aims to bring technology to market maturity

The HyLICAL project is funded under Horizon Europe and the Clean Hydrogen Partnership. Its goal is to advance magnetocaloric hydrogen liquefaction from a laboratory proof of concept (technology readiness level TRL 3) to an industrially relevant demonstrator level (TRL 5). According to the project, the expected efficiency gains compared to conventional processes are between 30 and 50 percent.

Magnotherm was founded in 2019 as a spin-off from the Technical University of Darmstadt and develops magnetic cooling systems for industrial applications. HZDR is a research center of the Helmholtz Association focusing on energy, health and matter.