© MAGNIFIER - stock.adobe.com

Global maritime trade is increasing. In 2018, shipping already accounted for around 2.9 percent of anthropogenic greenhouse gas emissions, with a rising trend. To date, more than 99 percent of the international shipping sector’s energy demand is met by petroleum-based fuels. As a climate-friendly propulsion technology, the solid oxide fuel cell (SOFC) is particularly promising for container ships. It operates with ammonia, methanol or hydrogen – the latest models can even switch between these fuels. However, it is still unclear what concrete usage pathways will look like. Consequently, the basis for statements on key figures such as costs, greenhouse gas emissions, overall process chain efficiency, land requirements and technology readiness level is also lacking. The EU project Fuelsome has defined possible future supply pathways for alternative fuels to facilitate this.

The Fuelsome project as a whole comprehensively investigates and develops a multi-fuel system with SOFC fuel cell, with the aim of reaching technology readiness level 4. A total of eight international partners are involved: the technology group AVL List, the research consortium Atena Scarl, the software company eBOS Technologies Ltd, the fuel cell manufacturer Elcogen Oy, the Technical University Politechnika Warszawska, the Zurich University of Applied Sciences and the Austrian research institute AEE Intec. AEE Intec is investigating how the key performance indicators (KPIs) of the usage pathways can be made comparable.

Structure diagram as a framework

The first part of the project has now been completed. The initial results are comprehensive structure diagrams that serve as a framework to investigate specific fuel pathways. They were created in an iterative and transdisciplinary process. The representation begins with the question of where the feed stock for fuel production comes from – in the physico-chemical sense, these are chemical elements such as carbon, hydrogen, nitrogen. The subsequent process steps are then processed: transport, storage and provision. Each usage pathway ends with the generation of propulsion energy on the ship, thus mapping the entire chain (well to wheel).

After defining the pathways, the challenge was to parameterise the individual process steps. For example, the researchers included the volumetric and gravimetric energy density of hydrogen and ammonia in gaseous and liquid states, the purity requirements necessary for operating the fuel cell, and all cost models for scaling. This enables calculation, scaling and optimisation in a specific computational model.

To link the previously theoretical pathways with practice, the researchers defined concrete use cases – exemplary applications of the usage pathways involving a specific combination of technologies.

The use cases are fundamentally independent of location. However, modelling in different case studies is to be based on real port locations, as these have a major influence on the results. The AEE INTEC team has created case studies for two ports of key importance in Europe: Rotterdam, Netherlands, and Valencia, Spain. For each location and its technological conditions, the respective KPIs are calculated and all data are evaluated with regard to important acceptance criteria. Three use cases relevant to practice are in focus and are outlined below.

© AEE INTEC

© AEE INTEC

Use Case 1: Hydrogen production via PEM electrolysis

This use case considers the production of hydrogen using proton exchange membrane (PEM) electrolysis, powered by electricity from wind and solar energy. The PEM technology was chosen due to its good compatibility with fluctuating renewable energies. However, the model can also be applied to alkaline electrolysis or any other technology, provided corresponding data are available. Prior to electrolysis, water treatment is required, with key parameters also included in the model. The water demand in the model is not a fixed restriction, but an input parameter – interpretation is therefore left to the user.

The hydrogen produced in this use case is stored locally in a depleted natural gas reservoir. The gaseous hydrogen is then transported via pipeline to the port, where it is again stored in a former natural gas reservoir, ensuring that sufficient hydrogen is always available for refuelling. Geological storage was assumed, as such sites are generally available at many locations and often also near the coast. The data situation from studies is also relatively good. However, there are hardly any large-scale technical high-pressure storage facilities, and a simple extrapolation from small storage units does not lead to meaningful results. Fundamentally, as with the electrolysis technology: if parameters are known, other storage technologies can also be incorporated into the model.

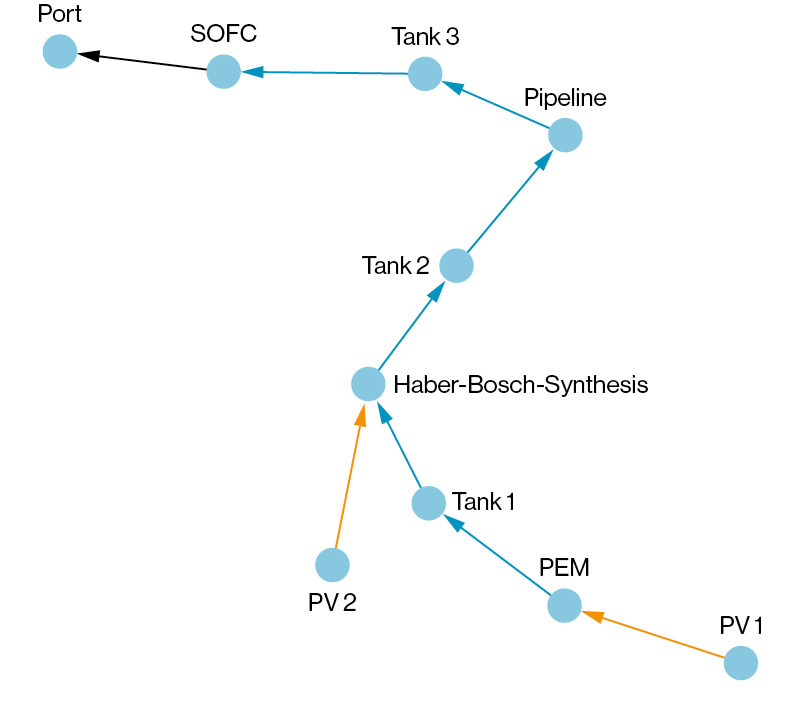

Use Case 2: Ammonia production via Haber-Bosch process

Ammonia (NH3) scores over hydrogen with its high volumetric energy density and easier storability, as it is already liquid at ambient pressure at temperatures below -33 °C. It can be produced on an industrial scale from hydrogen and nitrogen using the Haber-Bosch process.

This second use case initially involves the same steps as use case 1. However, after the hydrogen has been transported to the port, ammonia synthesis takes place there, also powered by renewable energies. The required nitrogen is obtained from ambient air using a cryogenic separation process.

Use Case 3: Methanol from hydrogen and biogas

The third use case focuses on the fuel methanol. Like the first two use cases, this one also begins with hydrogen production and transport to the port. There, biogas is also produced via anaerobic digestion. The raw materials for this can include biogenic residual or waste materials or manure. The biogas then needs to be purified: CO2 and CH4 (methane) from the biogas are required for methanol synthesis, while components such as hydrogen sulfide or ammonia must be removed. Methanol can then be synthesised from green hydrogen and the mixture of CO2 and methane.

Simulation tool currently under development

Preliminary calculations and evaluations of the usage pathways already exist, but they are still quite rough. The direct use of hydrogen has the advantage of requiring fewer conversion steps, which increases efficiency and reduces investment costs. However, the technology readiness level is lowest for direct hydrogen use, primarily due to the lack of infrastructure. In methanol production from biogas, on the other hand, the costs of CO2 capture have a very strong impact on fuel costs. However, these initial data are not yet robust enough for concrete comparisons between use cases or even for decisions.

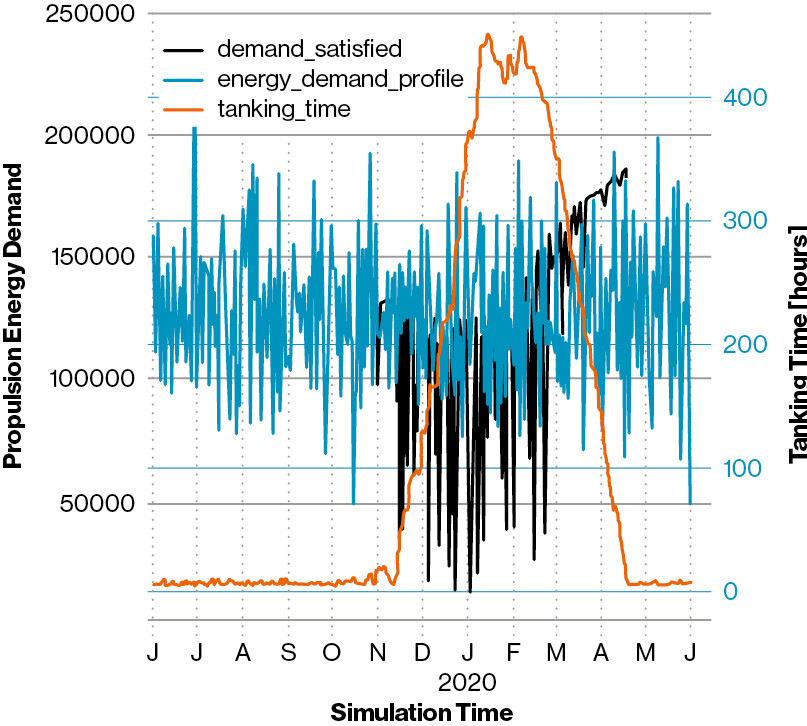

The researchers are currently working on developing a reliable and more precise simulation tool, which will also be able to calculate fuel pathways with temporal resolution. The software tool will be completed by the end of 2025 and will also be accessible to experts outside the project. In a workshop, the project results as well as the tool are expected to be presented to interested port companies in April 2026. This will enable them to use a consistent computational model to map the potential at their specific locations, taking their resources into account. Interested parties can already register with AEE INTEC for the workshop.

About AEE INTEC

AEE – Institute for Sustainable Technologies (AEE INTEC) was founded in 1988 and is now one of Europe’s leading institutes for applied research in the field of renewable energy and resource efficiency. In the three target group areas “Buildings”, “Cities & Networks” and “Industrial Systems”, as well as three technology workgroups “Renewable Energies”, “Thermal Storage” and “Water and Process Technologies”, the range of R&D projects carried out extends from basic research projects to the implementation of demonstration plants. Since 2015, AEE INTEC has been a member of Austrian Cooperative Research – ACR.