Standards (in Germany: Normen) provide legal certainty. For example, they can be referenced in laws as an option for compliance. Standards define interfaces between individual sectors and strengthen international trade by granting market access for products and services. Through cooperation with science and research in standardization committees, standards enable early strategic decisions for the implementation of new technologies. They also contribute to consumer safety by setting minimum standards and safety requirements and updating them as necessary to reflect current knowledge – often voluntarily, before laws come into effect.

In the gas supply industry, German standards regulate, for example, the quality of the energy carrier and define interfaces. This benefits trade and cooperation among companies. Standards also improve consumer safety by setting requirements for climate-friendly operation of pipeline systems or for inspection cycles and the quality of components.

In this context, the collaborative project “Standardization Roadmap for Hydrogen Technologies”, funded by the German Federal Ministry for Economic Affairs and Energy (BMWK), actively supports the ramp-up of the hydrogen market by helping to develop a comprehensive technical regulatory framework for hydrogen technologies in Germany.

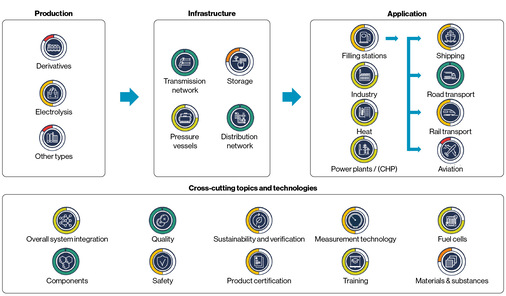

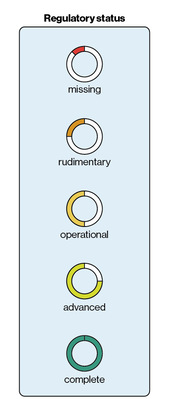

Launched in January 2023, the project provides an overview of the status quo of standardization in the field of hydrogen technologies in Germany, records the requirements and challenges for the entire value chain of the hydrogen economy, and derives necessary actions for future technical regulations. Based on these recommendations, concrete standardization projects are initiated and implemented.

Everyone at one table

“With the standardization roadmap, transparency has been created in the field of technical regulation for hydrogen technologies. It constitutes a round table for all stakeholders,” says Dennis Klein, Head of the Standardization Roadmap at DVGW (German Technical and Scientific Association for Gas and Water). Together with the German Institute for Standardization (DIN), DVGW is project leader and initiator of the initiative. Also participating are the German Commission for Electrical, Electronic & Information Technologies (DKE) in DIN and VDE, the Association for Standardization and Advancement of Railways (NWB), the German Association of the Automotive Industry (VDA), the Association of German Engineers (VDI), and the German Engineering Federation (VDMA).

“All relevant stakeholders and rule-setters worked together on a cross-sectoral, coherent and coordinated roadmap that covers the entire value chain from production to application,” Klein explains, highlighting the advantages of the concept. This collaborative approach is characteristic of Germany’s technical rulemaking and ensures that the multitude of ongoing activities, initiatives and projects in the field of hydrogen technologies related to standardization are integrated. In addition, duplication of work is avoided as a far-reaching standardization network is established at the European and international levels.

© DVGW

Funding accelerates standardization

The basis for this was initially a joint analysis of the existing regulatory frameworks for hydrogen that can already be used in Germany, which is made publicly and freely available in a continuously updated database (see note at the end of the article). Building on this, a gap analysis was carried out to identify the necessary standardization needs, which were then consolidated into recommendations for action in a roadmap. These recommendations were developed in 40 working groups of the standardization roadmap in close coordination with experts from the relevant standardization committees. On this basis, the latter were able to apply to the BMWK for funding for the implementation of a standardization project. “A large number of projects only became possible thanks to this funding, which otherwise would not have been carried out at all or only with significant delays under normal circumstances,” emphasizes DVGW staff member Klein.

In the meantime, 191 standardization projects have been launched and 312 recommendations for action have been issued. Sixty-nine so-called implementation projects received funding, of which six have already been completed. By the end of the year, it is expected that 27 implementation projects will be completed.

Of the 69 funded standardization projects, around 47 are at the national level, 14 at the European level and eight at the international level. Thirteen address the topic of production, eighteen infrastructure, eighteen application, fifteen quality infrastructure, and five continuing education, safety, and certification.

The concrete benefit of the standardization work lies in the fact that it is transparent and publicly accessible to all users. A standardization roadmap prevents duplication, builds on each other efficiently and in a coordinated manner, and defines the best state of information made possible by the exchange and sharing of knowledge among experts. For example, as a result of project funding, findings from German research on safety requirements for pressure vessels, pipelines, and components have been incorporated into the standards. This integration of national research into standardization is a hallmark of the German approach. This was made possible by funding experts who invested their time in this implementation.

“This will greatly accelerate coordination and hydrogen projects in the future,” standardization expert Klein is certain. For example, in the case of pipeline networks, it will no longer be necessary to test every material individually for hydrogen suitability. A standard provides the assessment for the material to be used and replaces individual tests that previously took several days. This, in turn, reduces time and costs for each application and also facilitates the work of manufacturers such as steel producers. The background here is that standardized instructions for planning, construction, and maintenance are already available and also provide relief in the event of damage.

Valuable input from the Hydrogen Innovation Program

Thanks to its expertise in the field of hydrogen, DVGW and its members in Germany have made a significant contribution of knowledge and helped to complete the H2 regulatory framework, says Klein. Thirty of the 69 implementation projects alone have benefited from this. Key regulatory frameworks, especially in the area of pipeline infrastructure, storage, and applications, fall under the responsibility of DVGW and its DIN Standards Committee NAGas.

Valuable input is provided here, among other things, by the DVGW Hydrogen Innovation Program, launched in 2020 in Germany with a budget of 15 million euros. Various findings from this program have been incorporated into the development of regulations and standards. Klein cites two examples: one is H2 safety, specifically hazardous areas at pipeline outlets to the atmosphere, in connection with the implementation project G 442 “Explosion Hazard Areas at Pipeline Outlets to the Atmosphere.” The second concerns standardization projects on the molecular H2 tightness of valves as well as the H2 tolerance of valves in general and of shut-off valves in particular. These standards form the basis for the new DVGW technical bulletin G 405 “Conversion of Existing Valves to Hydrogen,” which helps professionals convert existing systems to hydrogen.

National, European and international standards

Depending on complexity and need for discussion, the development of a standard or regulatory framework takes between one and three years, expert Klein explains. In Germany, it is recognized that the need for coordination is usually greater at the European or international level. The first step is to define the right framework. For example, an electrolyzer is an international product and therefore requires an international standard. “With regard to exports, there is no point in writing a rule or standard just for Europe or Germany,” Klein points out. The same applies to quality criteria for hydrogen. After all, hydrogen is not produced only in Germany, but throughout Europe and is also likely to be imported from around the world.

It is different in the case of infrastructure. With regard to the hydrogen backbone, Klein states: “This is a European project. Accordingly, we need European and national regulations here.” After all, there will be no hydrogen pipelines to China or the USA.

Internationally, DVGW sees Europe, and particularly Germany, as pioneers in hydrogen. An additional effect is expected from the standardization roadmap. “Thanks to this funding, Germany is in a position to take a leading role in European and international projects and to advance standards specifically in line with the National Hydrogen Strategy,” Klein emphasizes.

Focus also on training and continuing education

An important part of the standardization work is the topic of training and continuing education. This was addressed by Working Group 5 (Continuing Education, Safety, Certification) of the German standardization roadmap. Among other things, DVGW and its DIN Standards Committee NAGas are preparing a technical report. This is intended to help qualify professionals for the safe handling of hydrogen so that they are prepared for the transformation to a climate-neutral future with hydrogen. The insights gained are also to be reflected in DVGW's vocational training activities. DVGW’s vocational training branch in Germany already offers an extensive program of courses and seminars on hydrogen. These include, for example, the certification course “H2 Competence” or the “H2 Academy by DVGW”, which is run in cooperation with Siemens.

Overall, DVGW in Germany praises the efficient work within the framework of the “Standardization Roadmap for Hydrogen Technologies”. Of the total of 40 working groups, 35 have already completed their work, reports standardization expert Klein. The efficiency is also reflected in the total costs for the standardization project, which amount to just under 10 million euros. “Standardization is important, but it also has to be kept in a healthy balance,” Klein says. With regard to the sometimes high bureaucratic effort in the construction sector, he emphasizes: “A hydrogen economy must function safely, but at the same time must also be lean.”