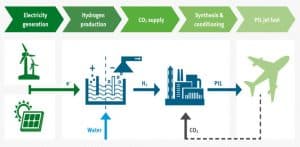

The key element of power-to-liquids is hydrogen, which is generated through wind or solar power and synthesized in a PtL system by using carbon monoxide or dioxide (O, CO2) to create hydrocarbon. The synthesized substance is subsequently processed into liquid fuel that meets the standards and can replace the large fuel amounts used in aviation (see fig. 1).

PtL production

There have so far been two methods to create PtL, both in very advanced stages of development: The Fischer-Tropsch and the methanol pathway. There is hardly any difference in energy demand between the two. The integration of high-temperature electrolysis (SOEL) and a potential CO2 extraction from air could lead to PtL production efficiencies of between 45 and 63 per cent.

High-temperature electrolysis utilizes the waste heat of several hundred degrees Celsius from synthesis, which leads to a significantly lower electricity demand that partially closes the gap to low-temperature electrolysis. PtL plant efficiency increases by 5 to 14 percentage points (depending on design and technical maturity), although the technology readiness level of the low-temperature version (8 to 9 of 9) is considerably more advanced than the one of the high-temperature application (5 to 6).

The required process components have been in widespread use for decades (Fischer-Tropsch synthesis, methanol synthesis, purification) or have become established but not employed for larger production volumes (low-temperature electrolysis). The PtL methanol production by Carbon Recycling International in Iceland and Sunfire’s PtL demonstration system in Dresden, Germany, have showcased promising avenues for the system integration and technical development of high-temperature electrolysis and air extraction.

Because of their lower energy demand, the best …

0 Comments